About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-12-07 10:21:57

date:2019-12-07 10:21:57

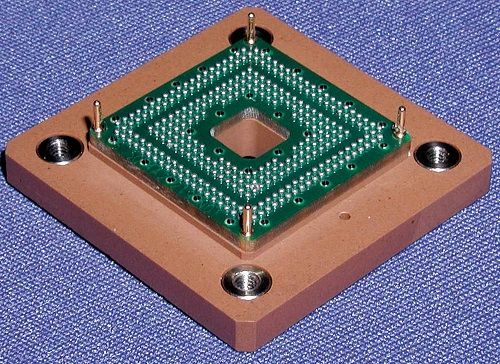

BGA rework process

Since the solder joint of the BGA is at the bottom of the device, it is invisible, so it is more difficult to rework compared to QFP and other peripheral pins. It is not a big problem when disassembling the BGA. However, when re-soldering the BGA, the rework system is required to be equipped with a spectroscopic vision system (also known as the bottom reflection optical system) to ensure accurate centering when mounting the BGA. The equipment suitable for rework BGA includes hot air rework station, infrared heating rework station, hot air Infrared rework system, etc.

1.BGA rework process

The BGA rework steps are basically the same as those for traditional SMD as below.

A. Remove the chip

B. Clean PCB pads and component pins;

C. Applying flux or solder paste:

D. Place the component:

E. Welding

F. Inspection

The following takes the BGA5000 series hot air rework system as an example to introduce the BGA rework process.

(1) Disassembly of BGA

A. Place the surface mount board that needs to be disassembled on the workbench of the rework system.

B. Select a square hot air nozzle that matches the size of the device, and install the hot air nozzle on the connecting rod of the upper heater

C. Attach the hot air nozzle to the device, pay attention to the distance around the device should be uniform. If there are components around the device that affect the operation of the hot air nozzle, these components should be dismantled firstly, and they should be reset after soldering.

D. Select a suction cup (nozzle) suitable for suctioning the device that needs to be disassembled, adjust the height of the vacuum suction pipette device , touch the suction cup to the top surface of the device, and turn on the vacuum pump switch

E. Set the disassembly temperature curve. Note that it must be set according to the specific conditions of the device size and PCB thickness. The disassembly temperature of the BGA is about 15 ℃ higher than that of the traditional SMD.

F. Turn on the heating power and adjust the hot air volume. Generally, the air volume can be adjusted to the maximum when disassembling.

G. When the solder is completely melted, the device is sucked by the vacuum pipette.

H. Pick up the hot air nozzle, turn off the vacuum pump switch, and catch the removed device

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn