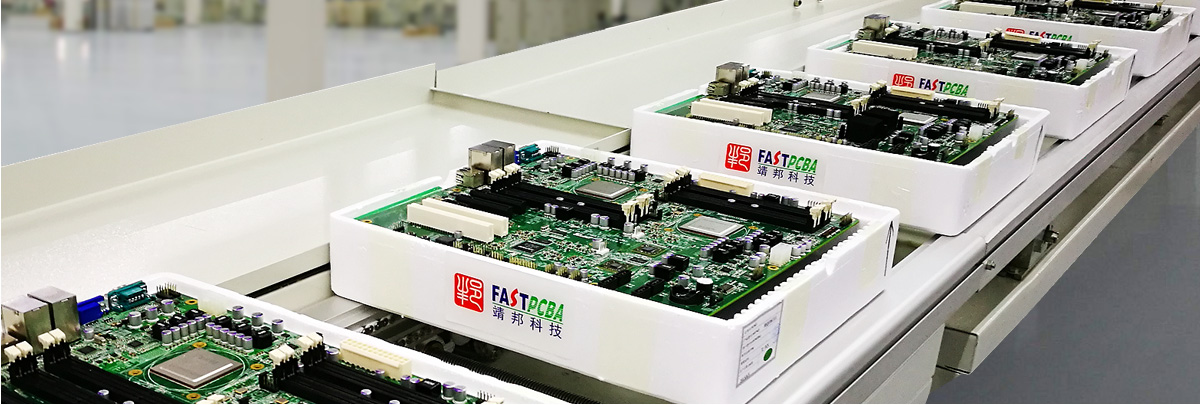

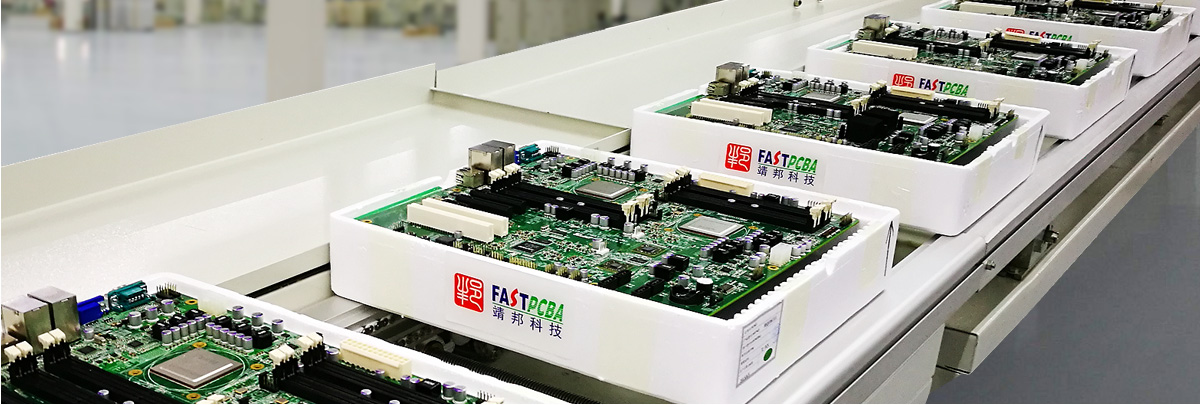

Printed Circuit Board Assembly Service

Printed Circuit Board Assembly ( PCBA ) is one of our core services FASTPCBA. From rigid , flexible , rigid-flex , multilayer printed circuit boards manufacturing to assembly, FASTPCBA is your one-stop PCBA partners.We provide our customers with PCBA solutions and services worldwide. Especially more than 80% PCB and PCBA are exported to oversea market. We have full of confidence to meet your quality level.

Check out this list of some of the high-quality PCB Assembly Services we offer:

1. One-Stop PCB Manufacturing and Assembly :

Fast, high precision, complicated, high quality a turnkey start-to-finish solution : PCB Manufacturing + Components Sourcing + PCB Assembly + Cable & Wire Harness Assembly + Box Build Services, meets all your needs.

2. Multiple PCB Assembly Services:

SMT, THT, Mixed Assembly, Package on Package (POP), Rigid PCBs, Flexible PCBs, Rigid-flex PCBs, HDI PCBs, Gold-Plated PCBs, High Frequency PCBs, etc. - if there's a type of printed circuit board that can be assembled, we almost surely do it.

3. Flexible Volume Assembly Alternatives:

• Prototype PCB Assembly: See how well your PCB design works before generating a large order.

Our quality prototype PCB assembly allows us to deliver a quick prototype, so you can identify any potential challenges in your design fast and

optimize the quality of your final boards.

• Low-Volume, High Mix PCB Assembly: If you require a number of different boards for specialized applications, FASTPCBA Is your best choice.

• High-Volume PCB Assembly: We are equally as skilled at cranking out large PCB assembly orders as we are at delivering small ones.

• Consigned & Partial PCB Assembly: Our consigned PCB assembly services meet IPC Class 3 standards, are ISO 9001:2015-certified, ISO 14001:2015-certifiedand are RoHS-compliant.

• Full Turnkey PCB Assembly: Also ISO 9001:2015; ISO 14001:2015; ISO 13485:2016; IATF 16949:2016 certifiedand are RoHS-compliant, our turnkey PCB assembly allows us to take care of your entire project from start to finish, so you can step in and start taking advantage of the finished product right away.

4. Components Sourcing:

We have years of experience and stable relationships with authorized electronic components manufacturers and distributors, we can make purchase in full accordance with the customer's designated supplier. Can also help customers reviwe and improve the supply chain, identify the specifications of electronic components, lower the cost and avoid the introduction of any defective products. All parts go through 100 percent quality inspection before use, so you always get real, quality parts.

Comprehensive Quality Assurance

There is no shortcut for quality, and our goal just is to make well every printed circuit board. We have imported the advanced machinery from US, Japan, German and Israel to improve our production and technical ability. We have set a great example the PCB field of flying probe testing, buried and blind via and special controlled impedance. Finished PCB Assemblies are checked for proper component placement and functionality with a variety of methods including AOI Inspection, In-Circuit testing, and X-Ray inspection. We have a highly developed R&D division which has helped our factory successfully produce mechanical micro via, high density impedance and HDI.

Advanced Equipment:

|

Tin Paste Printing Machine

|

Reflow Machine

|

Wave Soldering Machine

|

|

YAMAHA Surface Mount Machine

|

MYDATA Surface Mount Machine

|

X-RAY Detector

|

|

AOI Equipment

|

Ultrasonic Cleaning Machine

|

Three Anti-paint Spraying Machine

|

|

SMT Material Counting Machine

|

Dry Oven

|

Transportation Vibration Testing Machine

|

ICT and Functional PCBA Testing

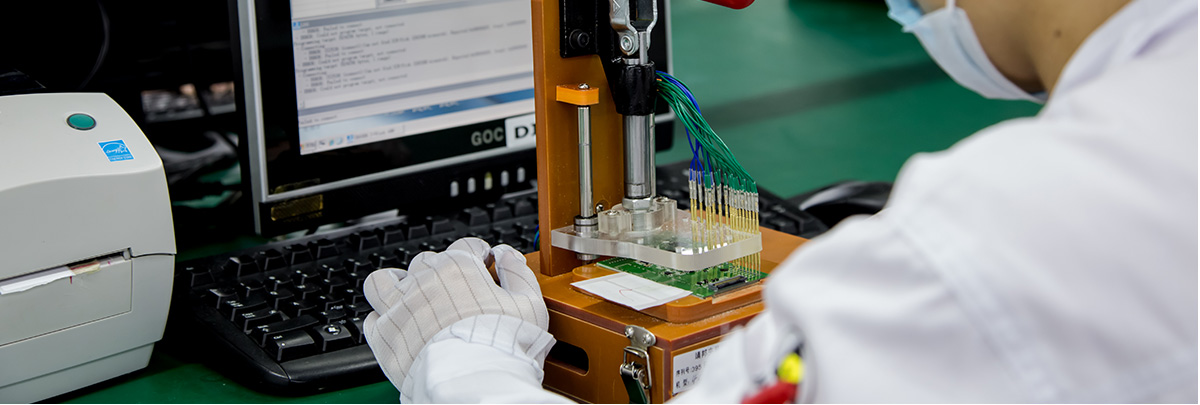

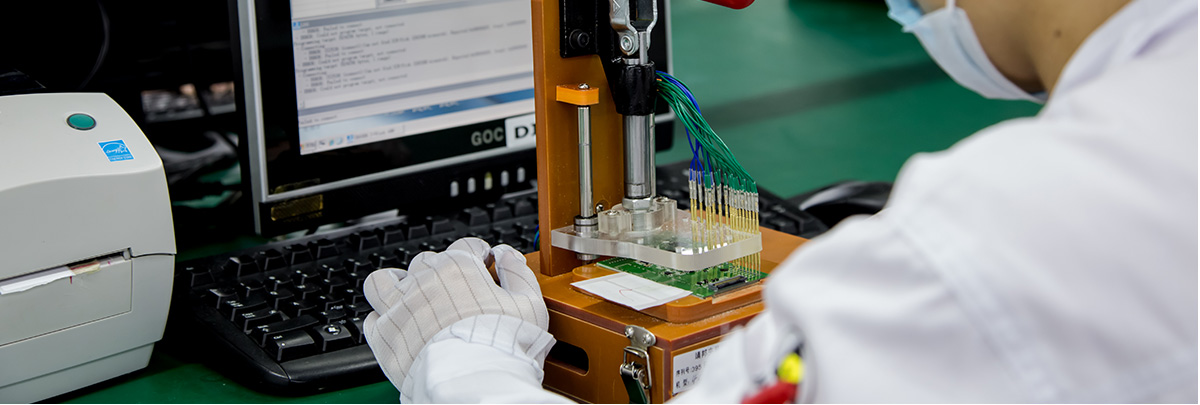

FASTPCBA is highly process focused with an adherence to J-STD-001 standards. All PCB assemblies are verified for part-placement accuracy; the use of critical checks such as signal integrity, functionality and performance to test specifications are fully incorporated into our printed circuit board assembly testing procedures. Comprehensive PCBA testing capabilities include functional circuits assembly testing equipment and in-circuit testing (ICT).

PCBA Testing With Multi-step Verification

To ensure the highest quality, FASTPCBA provides functional testing and in-circuit testing (ICT) services. Our test technicians and quality engineers are highly skilled, well-trained and will assemble and inspect to IPC-610 and J-STD-001 standards. Our manufacturing facilities and printed circuit board assembly processes have been audited and certified to these standards.

Once a PCBA is fitted with all necessary components and passed through the SMT assembly line, it is verified for compliance with customer CAD data using an inline AOI machine. Boards with bottom terminated components will go through x-ray inspection to ensure part-placement accuracy. Each assembly may then be subjected to in-circuit testing and/or functionally tested to customer specifications by a dedicated staff of test technicians.

The functional test stands used in the above process can be as simple as a set of electronic measuring devices on a workbench or as complex as a six-foot, rack-mounted, integrated testing system. While many customers choose to provide functional test equipment, FASTPCBA engineering staff has full capabilities to design and build customized functional testing systems.

Test, Engineering & PCB Assembly Capabilities:

All Circuit Board PCB Assembly testing and inspections are performed by experienced associates and are individually marked and recorded for accurate traceability.

FASTPCBA Detailed Assembly Capabilities Are Listed In the Table Below:

|

Feature

|

Capability

|

|

Quality Grade

|

Standard IPC 3

|

|

Order Quantity

|

1pc - 10,000+pcs

|

|

Build Time

|

1 - 3 days, 1 - 3 weeks, or scheduled deliveries PCB Spec Requirements

|

|

Max board size

|

700x460 mm

|

|

Board Type

|

Rigid PCBs, Flexible PCBs, Rigid-flex PCB, Metal core PCBs, HDI PCB, Gold-Plated PCB

|

|

Surface finish

|

HASL, ENIG, immersion gold, immersion silver, immersion tin, OSP…

|

|

Assembly Types

|

Surface mount

Thro-hole

Mixed technology (SMT & Thru-hole)

Single or double sided placement

Conformal coating

Shield cover assembly for EMI emission control

|

|

Solder Type

|

Lead-free - RoHS

|

|

Parts Procurement

|

full accordance with the customer's designated supplier.

Can also help customers reviwe and improve the supply chain

|

|

Function Test

|

100% Functional test

|

|

PCBA Testing

|

X-ray,AOI Test,Functional test

|

|

PCB outline

|

Square,circle,irregular(with jigs)

|

|

Sub-assembly

|

Plastic,metal,screen

|

Got a Project Ready for Printed Circuit Board Assembly?

We are ready to provide you with a high-quality, one-stop-shop experience for any and all of your PCB assembly requirements right now.

Please fill out the form below (or attach your Gerber files / Bom list By email: pcba23@pcb-smt.net), to get a free quote on PCB assembly services, one of our helpful staff will contact you shortly.

Pls double check your email if correct. Pls write your Company too so that you can get better services, Thanks.

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn