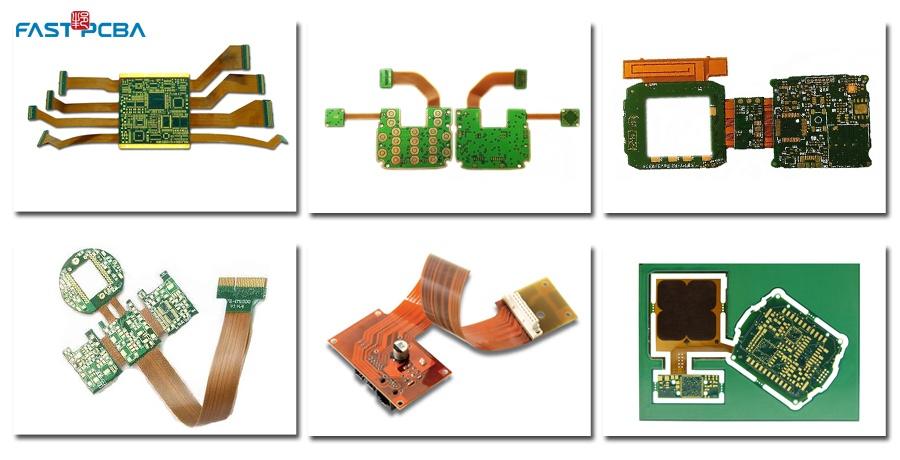

Rigid Flex PCB

Basic introduction to Rigid Flex PCB

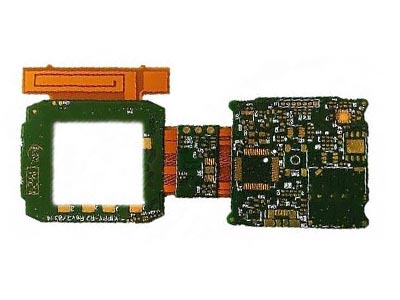

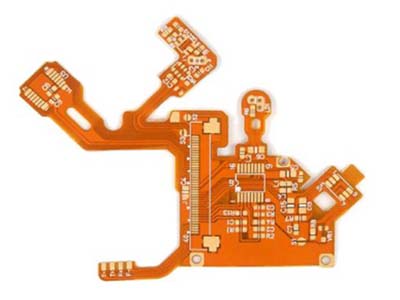

The birth and development of FPC and PCB gave birth to the new product Rigid Flex PCB. Therefore, Rigid Flex PCB is a flexible circuit board and a rigid circuit board. After pressing and other processes, they are combined according to relevant process requirements to form a circuit board with FPC characteristics and PCB characteristics.

Rigid Flex PCB production process

Because Rigid Flex PCB is a combination of FPC and PCB, the production of Rigid Flex PCB should have both FPC production equipment and PCB production equipment. First, the electronic engineer draws the circuit and shape of the Rigid Flex PCB according to the requirements, and then sends it to the factory that can produce the Rigid Flex PCB. The CAM engineer processes and plans the relevant documents, and then arranges the FPC production line to produce the required FPC , PCB production line produces PCB. After these two Rigid Flex PCBs come out, in accordance with the planning requirements of the electronic engineer, the FPC and PCB are seamlessly pressed through a pressing machine, and then a series of detailed links are finally made into Rigid Flex. PCB. A very important link, because Rigid Flex Circuit Boards is difficult and there are many detailed problems. Before shipment, a full inspection is generally required. Because of its high value, it will prevent the supply and demand parties from causing related profit losses.

Rigid Flex PCBs Types

|

Rigid-Flex PCB Capability |

||

| Items | Type | Normal Manufacturing Capability |

|

Standard |

Inspection Std. | IPC-6013 Class 2, IPC-A-600G Class 2, IPC-6013 Class 3 |

| Test Std. | IPC-TM-650,GB/T4677-2002 | |

|

Material |

DuPont | AL9111R, AP9121R, AP9131R, AP8525R |

| Panasonic | R-F775 11RB-M, R-F775 22RB-M, R-F775 21RB-M | |

| Taiflex | NDIR050513HJY,IDIR051013HJY,NDIR100520HJY,THKD200520 | |

| No Flow PP | VT-47N,VT-901 | |

| CCL | ITEQ IT180A , ShengYi 1000-2,N4000-13, Rogers4350B,4003C | |

|

Process capacity |

Layers | 2-20 |

| Thickness | 8-118mil | |

| Max dimension | 15.74X28 Inch | |

| Min precision Of Dim | ±4mil | |

| Min diameter of holes | 4mil (Laser drill); 6mil(mechanical drill) | |

| Aspect ratio | 16:1 | |

|

Min trace width/space wtidth of outer |

3.0/3.0mil |

|

|

Min trace width/space wtidth of outer |

3.5/3.5mil |

|

|

wtidth of outer layer(2OZ finished |

5/5mil |

|

|

Min trace width/space wtidth of inner |

3.5/3.5mil |

|

|

Min trace width/space wtidth of out layer(1OZ |

4/4mil |

|

| Min trace width/space wtidth of gridding circr |

5/5mil |

|

|

Min trace width/space wtidth of out layer(2OZ finishedcopper,Flex layer on top or bottom) |

5/5mil(1/3、1/2oz copper);6.5/5mil(1oz copper);8/5.5mil (2oz copper); |

|

|

Min distance Between drilling&conductor(via holes) |

7mil(2layers);9mil(3~6Llayers);11mil(≥7layers) |

|

|

Min distance Between drilling&conductor(com ponent holes) |

10mil(2layers);12mil(3~6Llayers);14mil(≥7layers) |

|

|

Min distance Between drilling&conductor(burie d &blind holes) |

7mil |

|

|

Min ring of inner layer(via holes) |

5mil(≤6 Layers) ;8mil(>8Layers) |

|

|

|

Min ring of inner layer(component holes) |

8mil(≤6Layers) ;11mil(>8Layers) |

|

coalescent location of rigid and flex |

1mm |

|

| HDI board | 1+n+1 | |

|

Surface treatment |

Plating Gold(Hard gold) | Normal:0.25-0.76um;Hard gold:0.76-2um; |

| ENIG | Ni:3--8um,Au:0.05-0.1um | |

| Immersion Tin | 0.80-1.20um | |

| Immersion Silver | 0.10-0.30um | |

| 0SP | 0.15-0.30um | |

| HASL | 2-40um | |

| HASL lead free | 2-40um | |

| Silver ink | 10-25um | |

|

Selective surface finishing |

ENIG+GOLD Finger; ENIG+HASL; ENIG+OSP; Soft gold+ GOLD Finger; Flash gold+HASL; immersion Tin+gold finger; Immersion sliver+gold finger; OSP +gold finger; Silver ink+Plating gold; Silver ink+ENIG. |

|

| Routing |

Outline Tol. |

+/-4mil |

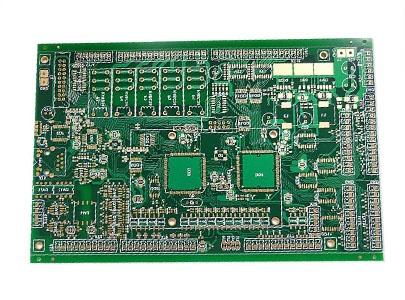

Printed Circuits Offers Quality Rigid-Flex Circuits

Rigid-Flex Circuits enable you to design circuitry to fit your end product, rather than building it around the circuit board – and they are a reliable, strong, and versatile way to do so.

At Printed Circuits, FASTPCBA specialize in bringing advanced rigid flex circuit designs to market, and we consistently build on over 20 years of manufacturing expertise. ISO9001, ISO13485, IATF16949 Certification. Our facilities offer world-class, cost-effective PCB production and PCB Assembly. For more information about what we can do for your PCB or PCBA project, get in touch with our team today.

FASTPCBA Service Center

FASTPCBA is Professional 20 Years PCB / PCBA Manufactuer in China, especially more than 80% circuit board are exported to oversea market. We offer 24*7 hours quotation service and engineering support. Offering: 1) PCB Assembly (including Components Sourcing & Testing) 2) Rigid PCB (1~48Layer) 3) Flexible PCB 4) Rigid-flex PCB 5) Aluminum PCB If you have any PCB projects, welcome to contact us. We sincerely hope to cooperate with you.

Products related to this product / Related Products

| I want to comment: | |

| *Content: |

(Content up to 500 words, 1000 characters) |

| Verification Code: | Invisibility?! |

samples

PCB Assembly

Multilayer PCB

Rigid-Flex PCB

Flexible PCB

HDI PCB

High Frequency PCBs

Gold-Plated PCB

Aluminum PCB

PCBA Board

PCB Prototype

Components

Add WeChat:18784674559

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

3/F. 1/B, 18-2 Yuquan East Rd. Yulv Village.

3/F. 1/B, 18-2 Yuquan East Rd. Yulv Village.  F:86-18784674559

F:86-18784674559

pcba13@fastpcba.cn

pcba13@fastpcba.cn

Altogether-article comment【I want to comment】