About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2022-01-24 17:05:34

date:2022-01-24 17:05:34

In the PCBA production process, electrostatic protection is crucial. Static electricity will damage electronic components invisibly, thereby affecting the quality of products. In the eyes of PCBA manufacturers, the quality of products depends to a large extent on the electrostatic protection of the production site. So what are the types of damage to electronic components caused by static electricity? How to do a good job of electrostatic protection in PCBA production?

The hazards of static electricity to PCBA

1. Absorb dust, reduce the insulation resistance of components and cause electronic products to short circuit.

2. Electrostatic discharge (ESD) damage, breakdown the chip, causing damage to electronic components can not work.

3. The magnitude of the electromagnetic field generated by electrostatic discharge is huge (up to several hundred volts / meter), and the electromagnetic field with extremely wide frequency spectrum (from tens of megabits to gigabits) makes electronic products damaged by electromagnetic interference.

4. Failure to meet the anti-static technology of the manufacturing plant will result in a high explosion or necrosis rate.

How does FASTPCBA control electrostatic hazards?

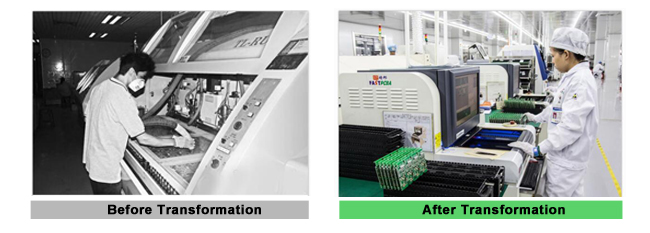

1. Dust-free anti-static workshop

5000 square meters of dust-free production workshop, the first layer of copper-clad, conductive layer, copper strip cylinder on the ground is 2.5 meters underground, to keep static electricity can be placed on the ground, anti-static workshop in line with certification standards.

2. High standard process

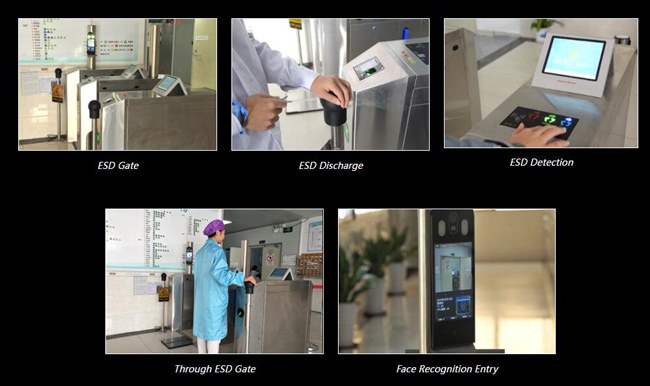

Anti-static detection and prevention process:

Release → Whether the test is completed → If it exceeds the standard, it cannot be entered

3. Anti-static work clothes matching

Workers must wear anti-static clothes, anti-static shoes, anti-static caps, anti-static gloves, and anti-static bracelets when entering the workshop. FASTPCBA strictly controls anti-static to ensure the life cycle of the product, which is truly assured and safe.

4. High standard production environment

Neat and clean workshop

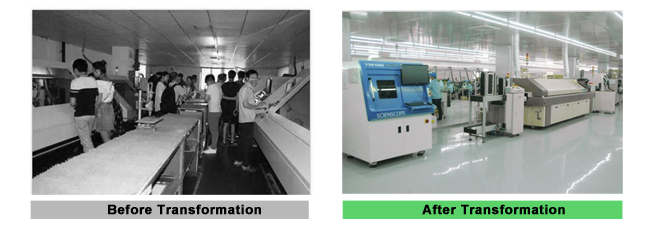

In fact, the attention to electrostatic protection in the pcba production industry has a long history. The difference in product stability between electronic equipment produced in China and those produced abroad is also largely reflected in the electrostatic protection during the production process. If China's electronics manufacturing industry wants to be enduring in the new era, it must keep improving in electrostatic protection.

FASTPCBA's product quality is guaranteed to be 100% static-free production, and real peace of mind is guaranteed.

More pcba information (www.jbpcba.com)

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn