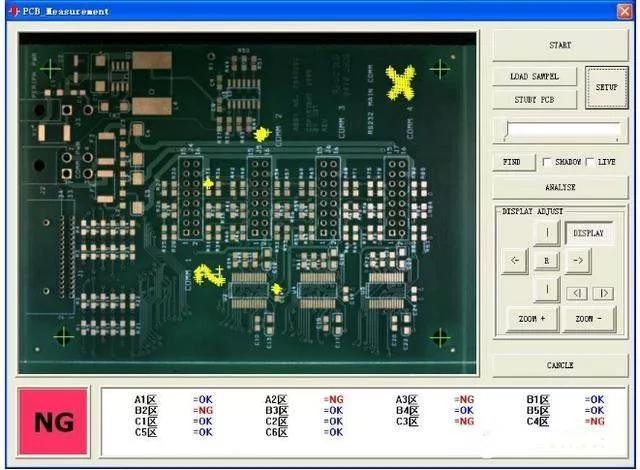

Whether it is a board made by someone else or a PCB board designed and made by yourself, the first thing to get it is to check the integrity of the board, such as tinning, cracks, short circuits, open circuits, and drilling. If the board is more effective Be rigorous, then you can check the resistance between the power supply and the ground.

Under normal circumstances, the self-made board will install the components after the tinning is completed, but if people do it, it is just an empty tinned PCB board with holes. You need to install the components yourself when you get it. . Some people have a lot of information about the PCB board they designed, so they like to test all the components at once. In fact, it is better to do it bit by bit.

PCB board under debugging

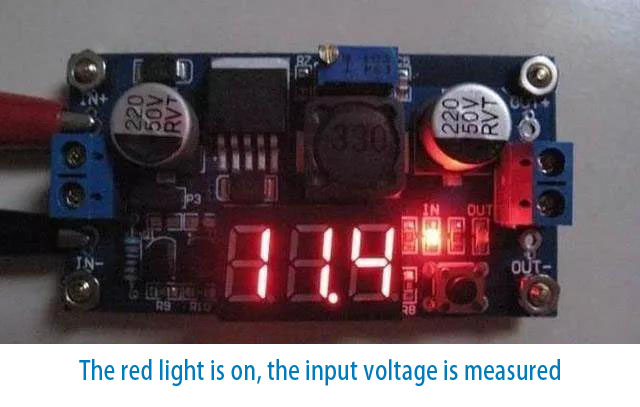

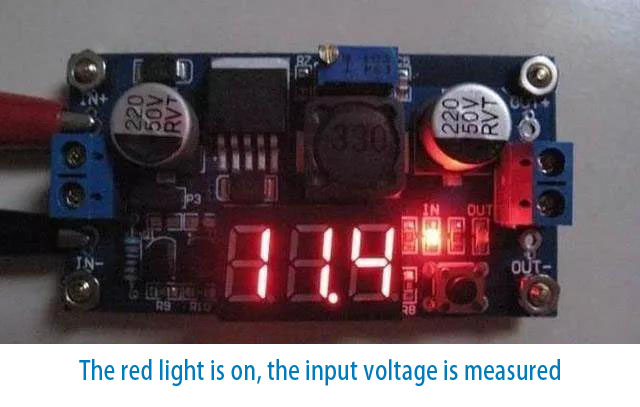

New PCB board debugging can start from the power supply part. The safest way is to put a fuse and then connect the power supply (just in case, it is best to use a regulated power supply). Use the stabilized power supply to set the overcurrent protection current, and then slowly increase the stabilized power supply voltage upwards. This process requires monitoring the input current, input voltage and output voltage of the board.

When the voltage is adjusted upwards, there is no over-current protection and the output voltage is normal, then it means that the power supply part of the board is normal. If the normal output voltage or over-current protection is exceeded, then the cause of the fault must be investigated.

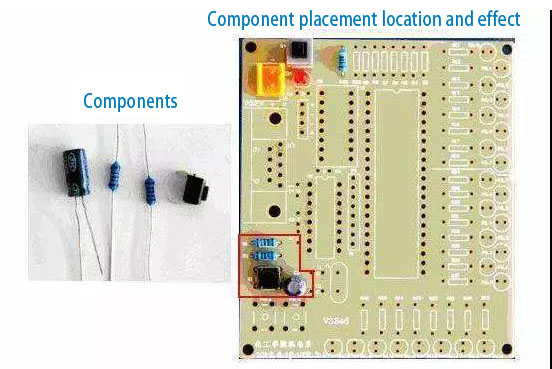

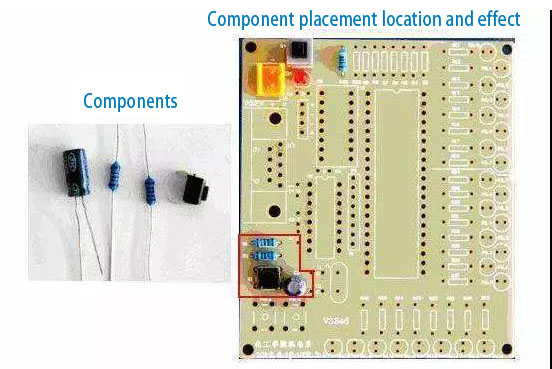

PCB circuit board component installation

Gradually install the modules during the debugging process. When each module or several modules are installed, follow the above steps to test, which helps to avoid some more hidden errors at the beginning of the design, or the installation of component errors, which may lead to overcurrent burning. Bad components.

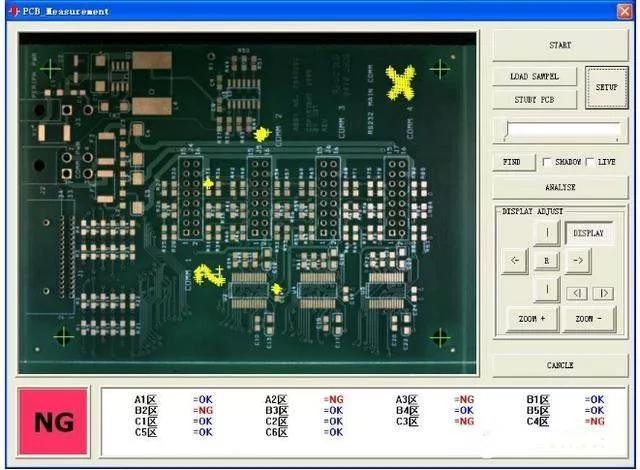

If there is a failure during the installation process, generally use the following methods to troubleshoot:

Troubleshooting method 1: Voltage measurement method

When over-current protection occurs, do not rush to disassemble the components, first confirm the power supply pin voltage of each chip to see if it is in the normal range. Then check the reference voltage, working voltage, etc. in turn. For example, when the silicon transistor is turned on, the BE junction voltage will be around 0.7V, and the CE junction will generally be 0.3V or less. When the BE junction voltage is found to be higher than 0.7V during the test (special triodes such as Darlington are excluded), then it is possible that the BE junction is open. In turn, check the voltage at each point to eliminate the fault.

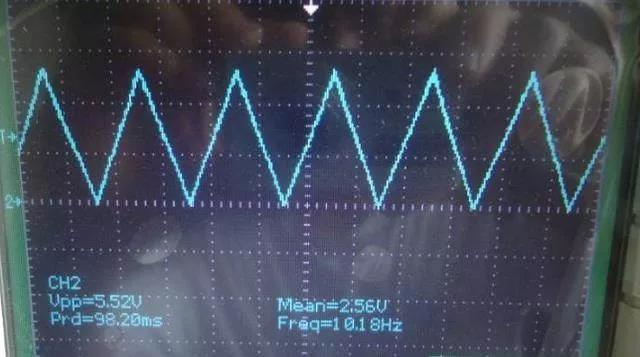

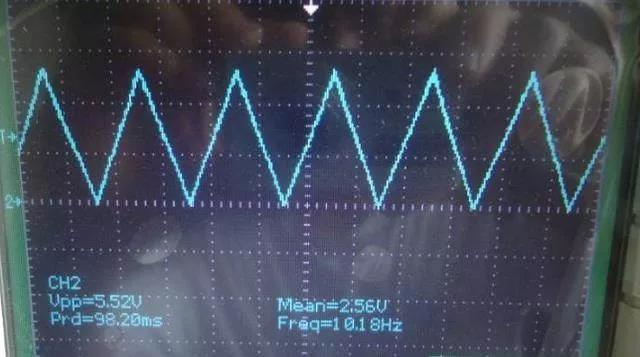

Troubleshooting method two: signal injection method

The signal injection method is more troublesome than measuring the voltage. When the signal source is sent to the input terminal, we need to measure the waveform of each point in turn to find the fault point in the waveform. Of course, you can also use tweezers to detect the input terminal. The method is to touch the input terminal with tweezers, and then observe the response of the input terminal. Generally, this method is used in the case of audio and video amplifier circuits (Note: hot floor circuit and high voltage circuit Do not use this method, it is prone to electric shock accidents). This method detects that the previous stage is normal and the next stage is responding, so the fault is not on the next stage, but on the previous stage.

Troubleshooting method three: other

The above two are relatively simple and direct methods. In addition, for example, the commonly said look, smell, listen, touch, etc., are engineers who need some experience to be able to detect problems. Generally, "look" is not to see the state of the testing equipment, but to see whether the appearance of the components is complete; "smell" mainly refers to whether the smell of the components is abnormal, such as the smell of burning, electrolyte, etc. The general components are It will emit an unpleasant burning smell when damaged.

"Listening" is mainly to listen to whether the sound of the board is normal under working conditions; about "touching", it is not to touch whether the components are loose, but to feel whether the temperature of the components is normal. For example, under working conditions, it should be cold. The components of the device are hot, and the components that generate heat are abnormally cold. Do not pinch it with your hands directly during the touching process, to prevent the hand from being burned by the high temperature.

Keyword: PCB board; Component installation; Circuit board troubleshooting method

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2020-08-27 16:16:02

date:2020-08-27 16:16:02

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn