About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-07-15 15:40:00

date:2019-07-15 15:40:00

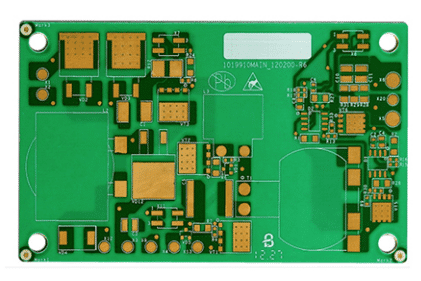

For turnkey pcb manufacturing, main features of PCB metal-based copper clad laminate

The metal-based copper clad laminate is generally composed of a metal substrate, an insulating medium layer and a conductive layer (generally a copper foil), that is, one or both sides of the surface treated metal substrate are covered with an insulating medium and a copper foil, and are thermocompression-composited.

(1) Classification of metal-based copper clad laminates. For turnkey pcb manufacturing,there are three common types of metal substrate, namely metal substrate,cladding metal substrate, and metal core substrate. The metal substrate is made of metal (aluminum, copper, iron, molybdenum, etc.), and the substrate is covered with insulating dielectric layer and conductive layer (copper foil); the coated metal substrate is a bottom substrate coated with a layer of glaze on the six sides of the metal plate, and is sintered to form a conductor circuit pattern by screen printing and sintering; the metal core substrate Generally with metal Invar (iron-nickel alloy) core material which is coated on the surface with a layer of organic polymer insulating medium, or it is laminated on a prepreg or a PET film, and covered with a conductor foil (some with an addition) The method directly forms a conductive pattern), wherein the metal substrate is the most common and the most used one.

For turnkey pcb manufacturing,metal substrates are classified into their compositions and can be classified into aluminum-based copper clad laminates, iron-based copper clad laminates, copper-based clad copper clads, and molybdenum-based clad copper clads. Metal-based copper clad laminates are classified into two types: normal metal-based copper clad laminates, flame-retardant metal-based copper clad laminates, high heat-resistant metal-based clad copper clads, high thermal conductivity metal-based clad copper clads, and ultra-high thermal conductivity metals base copper clad laminate, high frequency, microwave type metal-based copper clad laminate and multi-layer metal clad copper clad laminate.

(2) For turnkey pcb manufacturing,main characteristics of metal-based copper clad laminates. The properties of the metal-based copper clad laminate are mainly determined by the properties of the metal sheet occupying most of the thickness of the sheet.

1. Excellent heat dissipation performance. For turnkey pcb manufacturing, metal-based copper clad laminates have excellent heat dissipation properties, which is the most prominent feature of such panels. The PCB made of it can prevent the operating temperature of components and substrates loaded on the PCB from rising, and can also dissipate heat generated by components such as power amplifier components, high-power components, and large-circuit power switches. Among the different types of metal substrates, the metal substrate using copper as the substrate has the best heat dissipation. However, if the copper plate and the aluminum plate have the same volume ratio, the price of copper is high and the density is large, which is not suitable for the lightweight development of the substrate material. Not widely adopted. Only when a high heat dissipation metal substrate is manufactured, small amount copper plate is used . The aluminum plate has better heat dissipation than the iron plate.

2. Good machinability. For turnkey pcb manufacturing,the metal-based copper clad laminate has high mechanical strength and toughness, which is much superior to the rigid resin-based copper clad laminate and the ceramic substrate, so that the production of a large-area printed board can be realized on the metal substrate. Heavyweight components can be mounted on such substrates. In addition, the metal substrate also has a good flatness, and can be assembled on the substrate by hammering, riveting etc. On the manufactured pcb, the non-wiring portion can also be mechanically processed in terms of bending, twisting etc.

3.Excellent dimensional stability. There is a problem of thermal expansion (dimensional stability) for various copper clad laminates, particularly thermal expansion in the thickness direction (Z-axis), which affects the quality of metallized holes and lines. The linear expansion coefficient of the iron and aluminum substrates is much smaller than that of the general resin substrate, and is closer to the linear expansion coefficient of copper, which is advantageous for ensuring the quality and reliability of the printed circuit.

4. Electromagnetic shielding. In order to ensure the performance of electronic circuits, some components in electronic products must be protected from electromagnetic wave radiation and interference, and the metal substrate can act as a shielding plate to shield electromagnetic waves.

5. Electromagnetic characteristics. The substrate material of the iron-based copper clad laminate is an alloy having magnetic properties of an iron-based element (such as a ruthenium steel plate, a low carbon steel, a galvanized cold-rolled steel plate, etc.), it is used in tape recorder (VTR), floppy disk drive (FDD), servo motor and other small precision motors. The metal-based copper clad laminate serves as both a PCB and a small motor stator substrate.

(3) PCB application of metal-based copper clad laminates. For turnkey pcb manufacturing, the iron-based copper clad laminate and the silicon steel clad laminate have excellent electrical properties, magnetic permeability and pressure resistance, and the substrate strength is high. Mainly used in brushless DC motors, recorders, Integrating machine, spindle motors and intelligent drives.

Aluminum-based copper clad laminates have excellent electrical properties, heat dissipation, electromagnetic shielding, high withstand voltage and bending processability, and are mainly used in automobiles, motorcycles, computers, home appliances, communication electronic products and power electronics. The market for aluminum-clad copper clad laminates in metal PCB substrates is the largest.

Copper-based copper clad laminates have the basic properties of aluminum-based copper clad laminates, and their heat dissipation is superior to aluminum-based copper clad laminates, which can bear large currents and are used to manufacture PCBs for high-power circuits such as power electronics and automotive electronics, but copper substrate is of high density , high value, easy to oxidize, its application is limited, the amount is much lower than aluminum-based copper clad laminates.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn