About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2020-12-18 17:31:05

date:2020-12-18 17:31:05

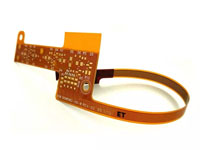

Flexible printed circuit (FPC) is a highly reliable and excellent flexible printed circuit board based on polyimide or polyester film. It has the characteristics of high density, light weight, thin thickness and good bending property.

The features of FPC are as follows:

1. Short: short assembly time

All lines have been configured to eliminate the connection of redundant cables;

2. Small: smaller than PCB

It can effectively reduce the product volume and increase the convenience of carrying;

3. Light: lighter than PCB (Rigid pcb board)

It can reduce the weight of the final product;

4 thin: thinner than PCB

It can improve the flexibility and strengthen the assembly of three-dimensional space in the limited space.

Advantages of flexible circuit board (FPC)

Flexible printed circuit board (FPC) is a kind of printed circuit made of flexible insulating substrate

1. It can be bent, wound and folded freely, and can be arranged arbitrarily according to the spatial layout requirements, and can be moved and expanded arbitrarily in three-dimensional space, so as to achieve the integration of component assembly and wire connection;

2. The volume and weight of electronic products can be greatly reduced by using FPC, which is suitable for the development of electronic products towards high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, portable computers, computer peripherals, PDA, digital cameras and other fields or products;

3. FPC also has the advantages of good heat dissipation and solderability, easy assembly and low comprehensive cost. The design of soft and hard combination also makes up for the slight deficiency of flexible substrate in the bearing capacity of components to a certain extent.

The disadvantages of FPC are as follows

1. High initial cost of one time: since flexible PCB is designed and manufactured for special application, the cost of circuit design, wiring and photographic plate is high. Unless there is a special need to apply soft PCB, it is better not to use it in a small amount of applications;

2. It is difficult to change and repair the flexible PCB: once the flexible PCB is made, the change must start from the base drawing or the light drawing program compiled, so it is not easy to change. Its surface is covered with a layer of protective film, which should be removed before repair and restored after repair, which is a relatively difficult work;

3. Limited size: soft PCB is usually manufactured by batch process when it is not common, so it can not be made very long and wide due to the size of production equipment;

4. Improper operation is easy to damage: improper operation of the assembly personnel may cause damage to the soft circuit, and the soldering and rework need to be operated by trained personnel.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn