About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2021-05-05 14:27:51

date:2021-05-05 14:27:51

HDI board is the most precise circuit board among PCB boards, and its board manufacturing process is also the most complicated. Its core steps mainly include the formation of high-precision printed circuits, the processing of micro-vias, and the electroplating of surfaces and holes. Next, let's take a look at the core steps of HDI PCB manufacturing.

1. Ultra-fine circuit processing

With the development of science and technology, some high-tech equipment is becoming more and more miniaturized and sophisticated, which requires higher and higher HDI boards.

The line width/line spacing of HDI circuit boards of some equipment has grown from 0.13 mm (5 mil) in the early days to 0.075 mm (3 mil), and it has become the mainstream standard. As a leading company in the HDI Allegro industry, Shenzhen Benqiang Circuit Co., Ltd.'s related production process has reached 38μm (1.5 mil), which has approached the industry's limit.

Increasing line width/line spacing requirements have brought the most direct challenge to the graphics imaging in the PCB manufacturing process. So how are the copper wires on these precision boards formed?

The current formation process of refined circuits includes laser imaging (pattern transfer) and pattern etching.

The laser direct imaging (LDI) technology is to directly scan the surface of the copper clad laminate with photoresist to obtain the refined circuit pattern. The laser imaging technology greatly simplifies the process flow and has become the mainstream in HDI PCB plate making. Process technology.

Now the semi-additive method (SAP) and the improved semi-additive method (mSAP) are more and more used, that is, the pattern etching method. This technical process can also realize conductive lines with a line width of 5um.

2. Micro-hole processing

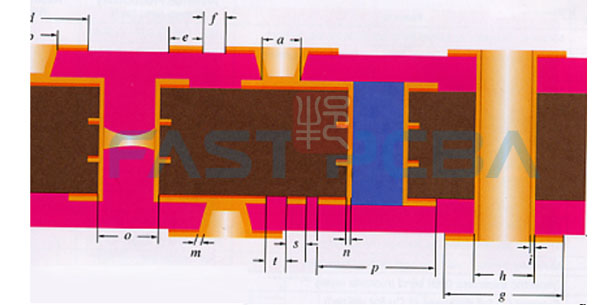

The important feature of HDI circuit boards is that they have micro vias (aperture ≤0.10 mm), and these holes are buried blind via structures.

At present, the buried blind holes on HDI boards are mainly processed by laser, but there are also numerical control CNC drilling.

Compared with laser drilling, mechanism drilling also has its own advantages. When laser processing the through hole of the epoxy glass cloth dielectric layer, the quality of the hole will be slightly worse due to the difference in the ablation rate between the glass fiber and the surrounding resin, and the remaining glass fiber on the hole wall will affect the reliability of the through hole . Therefore, the superiority of mechanical drilling at this time is reflected. In order to improve the reliability and drilling efficiency of PCB boards, laser drilling and mechanical drilling technologies have been steadily improved.

3. Electroplating and surface finishing

How to improve the plating uniformity and deep hole plating ability in PCB manufacturing, and improve the reliability of the board. This depends on the continuous improvement of the electroplating process, starting from many aspects such as the proportion of the electroplating solution, equipment deployment, and operating procedures.

High-frequency sound waves can accelerate the etching ability; permanganic acid solution can enhance the ability of the workpiece to decontaminate. The high-frequency sound waves will stir and add a certain proportion of potassium permanganate electroplating solution in the electroplating tank. This helps the plating solution flow evenly into the holes. Thereby improving the deposition ability of electroplated copper and the uniformity of electroplating.

At present, the copper-plated hole filling of blind holes is also mature, and copper filling of through holes with different apertures can be carried out. The two-step copper plated hole filling can be suitable for through holes with different apertures and high aspect ratios, and has a strong copper filling ability and can minimize the thickness of the surface copper layer.

There are many options for the final surface finish of PCB. Electroless nickel/gold (ENIG) and electroless nickel/palladium/gold (ENEPIG) are commonly used on high-end PCBs.

Both ENIG and ENEPIG have the same immersion gold process. Choosing an appropriate immersion gold process is very important for the reliability of installation welding or wire bonding. There are three types of gold leaching processes: standard replacement gold leaching, high-efficiency leaching gold with limited nickel dissolution, and reduction reaction leaching gold with mixed mild reducing agents. Among them, the reduction reaction has better effect of gold leaching.

For the problem that the nickel layer contained in ENIG and ENEPIG coatings is not conducive to high-frequency signal transmission and fine line formation, surface treatment and use electroless palladium/catalytic gold (EPAG) instead of ENEPIG to remove nickel to reduce metal thickness.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn