About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2020-10-27 11:51:48

date:2020-10-27 11:51:48

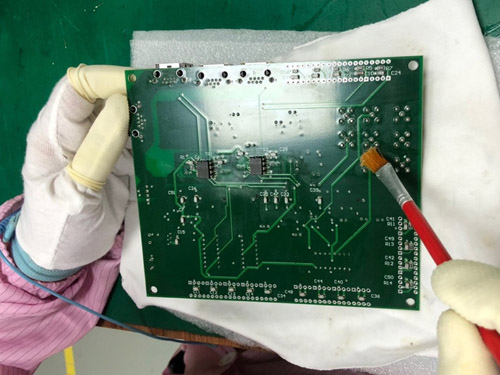

In the process of SMT patch processing, because there are auxiliary agents such as flux, some contaminants or spots will be generated after oxidation or high temperature, so in the end, many PCBAs need to be cleaned to be a perfect product. In terms of cleaning, whether solvent cleaning or water cleaning is used, it must undergo surface wetting, dissolution, emulsification, saponification, etc., by applying different methods of mechanical force to remove contaminants from the surface of the assembly board, and then rinse or rinse. Finally dry.

1. Wet surface

The decontamination medium forms a uniform thin layer on the surface of the washed object, which wets the surface of the washed object and swells the contaminants on the surface of the washed object. The condition of surface wetting is that the surface tension of the cleaning medium is less than the surface tension of the washing object. Adding some surfactants to the cleaning medium can significantly improve the wetting ability.

2. Dissolve

The main decontamination mechanism of organic solvent cleaning is dissolution. When selecting solvents, similar principles of compatibility should be followed. Polar solvents should be used for polar pollutants, and non-polar solvents should be used for non-polar pollutants. However, polar solvents and non-polar solvents are often mixed and used in actual production. Adding some surfactants to the organic solvent cleaning can improve the detergent's ability to dissolve the thread residue.

2.1. Ionic dissolution: Ionic dissolution refers to the dissociation of pollutants into ions in water. The dissolution of this ionic substance will increase the conductivity of water. Negative ionic contaminants on surface mount circuit boards include active substances in flux, reactants of active substances in flux and metal oxides, salt in hand sweat, polymers and solder in the manufacture of printed circuit boards. The salt in the residue. Such contaminants may cause poor electrical performance of electronic products or cause corrosion of solder joints.

2.2. Non-ionic dissolution: Non-ionic dissolution means that pollutants dissolve in water without changing the conductivity of the water. Typical non-ionic contaminants are flux bodies, such as polyvinylidene, dirt in hands, phase substances in water and similar compounds. These substances are not conductive, but they will absorb moisture, which will also cause a decrease in insulation resistance and SMT. Processing welding spot corrosion.

3. Emulsification

In the water cleaning and semi-aqueous cleaning process, a certain amount of emulsifier can be added to the water. When cleaning synthetic trees, curing and contaminants, these contaminants and emulsifiers emulsify and dissolve in water. Adding surfactants can improve emulsification.

4. Saponification

Saponification is a simple chemical process, and it is also a neutralization reaction. The penization reaction uses fatty acid salts. It makes the rosin and acid saponification reaction, so that the residue on the surface of the washing is dissolved in water and removed. The saponification agent will corrode the surface of aluminum and other metals. Therefore, when using the saponification agent, you should add the corresponding leveling agent and observe the compatibility of the saponification agent with the components and other materials. The addition of surfactants can promote the saponification reaction.

5. Chelation

Chelation refers to the addition of complexes to dissolve insoluble substances (such as heavy metal salts).

6. Apply mechanical force

Applying different mechanical forces can speed up the cleaning speed and improve cleaning efficiency.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn