About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-11-27 14:56:44

date:2019-11-27 14:56:44

Im-Sn plating

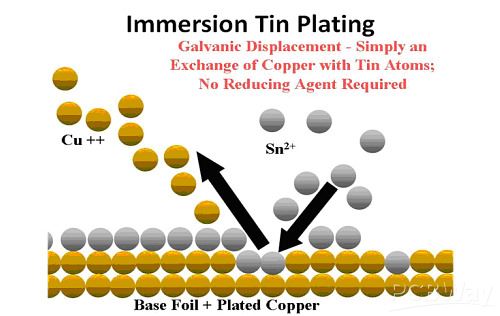

Im-Sn is the abbreviation of Immersion Tin, commonly known as immersion tin and melting tin.

Im-Sn plating is a pure tin layer formed on the surface of Cu through a substitution reaction.Because it is a substitution reaction, with the thickness increase of the plating layer, fewer and fewer pores allow copper ions to pass through the tin, and fewer and fewer Cu can be displaced, the reaction rate gradually decreases, so the thickness of the tin coating is limited, generally around 1um, and the tin is directly deposited on the Cu surface.

Compared with melting silver (Im-Ag), because silver metal has higher electromotive force than copper, immersion silver and copper react spontaneously. For immersion tin, the electromotive force of copper is higher than that of tin, that is, copper is more stable than tin, and copper ions are easily reduced to metal. Therefore, immersion tin requires additional additives to change the electromotive force difference between tin and copper, so that copper metal becomes copper ion, and tin ion becomes tin metal. Commonly used additives include tin salts, complexing agents, tin whisker inhibitors, etc.

Process characteristics

Im-Sn plating is mainly used for communication backplanes. It can obtain a satisfactory crimp hole size, and it is easy to achieve ± 05mm (± 0.002mil) accuracy. In addition, Im-Sn also has a certain lubricating effect, which is especially suitable for PCBA with a large number of crimp connectors.

1. Advantages

(1) Low cost (relative to ENG). (2) Compatible with lead-free requirements. (3) The storage period is relatively long. (4) The solderability is good.

2.Disadvantages

(1) Due to the limited of fingerprints and number of repairs, it is not recommended for communication line cards.

(2) The tin plating layer near the plug hole is easy to change color after reflow soldering. This is because the solder mask (commonly known as green oil) plugs holes and is easy to conceal the potion, and then flows out to react with the nearby tin layer during soldering.

(3) There is a risk of tin whisker. The risk of tin whisker depends on the potion used for immersion tin.Some tin layers made of potion are likely to produce tin whisker, and some are not easy to produce tin whisker.

(4) Some immersion tin formulas are not compatible with solder mask, and have a serious erosion effect on solder mask, which is not suitable for the application of fine solder mask bridge.

3.Various supplier resources

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn