About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-06-12 17:10:00

date:2019-06-12 17:10:00

In SMT assembly process,how to improve the appearance quality of PCB solder mask

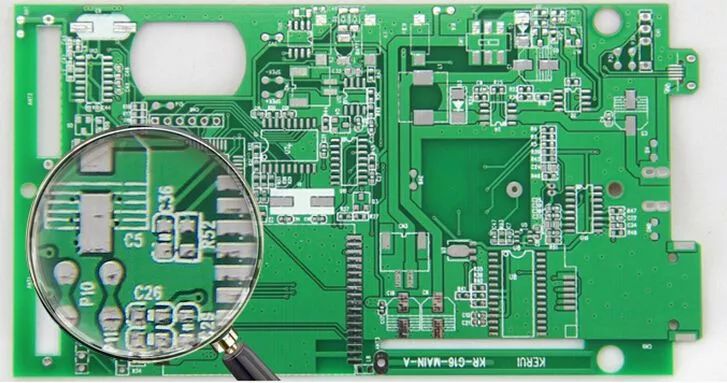

People talk about the trend of printed circuit board development, printed circuit boards tend to be high-precision, high-density and high-reliability development direction. But on the other hand, the appearance of PCB has become more and more strict. Like the solder mask “sheath” on the printed circuit board, in addition to the required a certain thickness and hardness, solvent resistance test and adhesion test standards, the surface color is uniform and shiny, no garbage, no unnecessary traces.

quality of the solder mask is not only the embodiment of the technical level and management level of the enterprise, but also directly affects the order of the enterprise. Therefore, how to improve the appearance quality of the printed circuit board has become an urgent problem to be solved in each PCB factory.

Factors affecting the appearance quality of solder mask

1. Printing: photosensitive solder mask ink screen printing craft, flatness, environmental purification, screen printing using barrier tape and ink printing pressure, printing preparation before printing will affect the appearance quality, according to the actual production situation, the most influential factors is the first three types, and the blade is not easy to produce flat knife marks on the solder mask printing surface; when used tape improperly , it is easy to make the colloidal solvent and surface particles in the ink form a barrier on the surface of the garbage.

2. Exposure: In the process of contacting the soldering ink, since the flux is not completely cured, the solder resist layer and the solder paste are easy to produce marks, which is the main reason that affects the appearance quality of the solder paste. The solder mask ink is developed by a general horizontal transfer type development, the solder mask is not cured completely, the developing machine drive wheel, the pressure roller etc are liable to cause surface damage, and roll marks are generated, thereby affecting the appearance quality of the solder mask.

In addition, incorrect exposure energy can also affect the gloss of the solder mask, but this can be controlled by a wedge watch.

3.Curing: The soldering resist temperature is not uniform after curing, which tends to cause the solder paste to be uneven in color. When the temperature is too high, it may even cause local yellowing and blackening, which may affect the beauty of the solder. When the solder ink is screen-printed, since the screen printing surface is not flat, after a period of screen printing, the surface of the scraper becomes uneven, and thus scratches are left on the surface of the solder mask layer.

Therefore, the operator must always pay attention to the surface condition. Once the scraper trace is found, the scraper should be wiped immediately to ensure smoothness. In order to obtain a printed board with good appearance quality, a clean screen printing chamber plays a key role. All places that come into contact with the printed circuit board (including workbench, screen frame, blotter paper, BLOCKOUTS tape) and the printed circuit board itself must use roller dust to remove dust.The room must be cleaned during the turnaround. The clean room must be worn with special Clothes, wear a hat, and follow the rules of the wind bath. At the same time, air purification protection around the plant is also crucial.

If this condition happens, you can regularly sprinkle water around the factory to remove dust. Development: The flux is not fully cured on the development surface, making it easy to leave the impression of a roller.

FASTPCBA SMT processing: Therefore, it should be considered on the device. The first drive roller must use a soft material or roll coating, a soft PVC "O" ring, a roller, a water squeezing roller made of a soft rubber roller; secondly, ensure the stability of the entire transmission system; finally,the developing roller and a water squeezing roller are periodically cleaned to remove dirt on the roller and remove it, thereby producing such anti-rolling marks. In order to improve the appearance quality of PCB solder mask film, comprehensive control is carried out from the aspects of craft, raw materials, equipment, operators, etc., especially for screen printing parameters, exposure and development, and strict control after curing. The quality of the solder mask layer of the printed circuit board can fully meet the customer's needs.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn