About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-10-17 16:15:24

date:2019-10-17 16:15:24

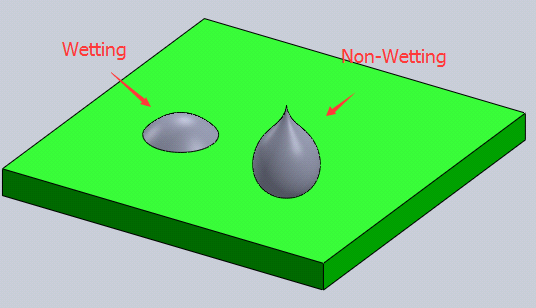

Online PCB Manufacturing poor tin defects analysis and solutions

Online PCB manufacturing defect reason analysis

1. Component leads and pads are poorly solderable and difficult to tin on.

2. Flux activity is low, and the oxide layer on the leads and pads cannot be completely removed.

3. The solder pot has a low liquid level and the solder does not completely cover the pad.

4. The preheating temperature is low, the flux activity is not fully activated, and the oxide layer is not completely removed.

5. Tin pot temperature is low, solder wetting time and temperature are not enough

6. The plate speed is too fast, the solder is too late to fill

Solutions

1.During Online PCB manufacturing, using a slightly more active flux or increasing the amount of flux used

2. Adjust the immersion tin depth and replenish the solder

3. Adjust the preheating temperature

4. Adjust the temperature of the tin pot

5. Adjust the transmission speed

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn