About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2020-09-29 09:19:52

date:2020-09-29 09:19:52

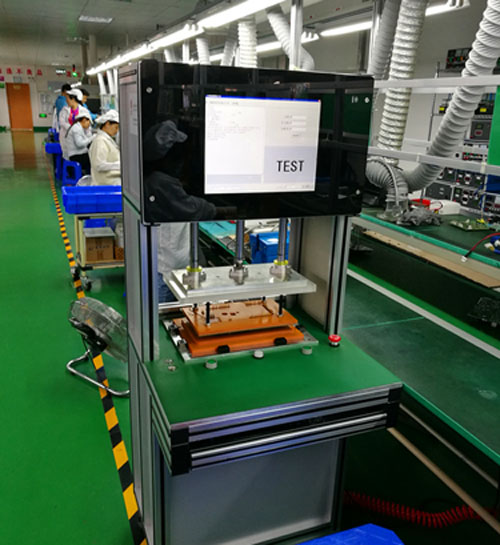

PCBA testing is an important link in the PCBA process to control product quality. It is to check whether the PCBA board has sufficient reliability to complete the future work. It is a key step to ensure the quality of production and delivery. Generally speaking, PCBA reliability test is divided into ICT test, FCT test, fatigue test, simulated environment test, and aging test.

ICT test

The ICT test is mainly to test the welding condition of the components, the on-off of the circuit, the voltage and current values, the fluctuation curve, the amplitude, and the noise.

FCT test

FCT testing requires IC program firing, then connect the PCBA board to the load, simulate user input and output, perform functional testing on the PCBA board, find the problems in the hardware and software, realize the joint debugging of the software and hardware, and ensure the normal front-end manufacturing and welding.

Fatigue test

The aging test is mainly to sample the PCBA board, simulate the high-frequency and long-term operation of the user's use of the function, observe whether there is failure, and judge the probability of failure in the test, so as to feedback the working performance of the PCBA board in the electronic product.

Simulated environment test

The simulation environment test mainly exposes the PCBA board to extreme temperature, humidity, drop, splashing, and vibration, and obtains the test results of random samples to infer the reliability of the entire PCBA board batch product.

Aging test

The burn-in test is a long-term power-on test on the PCBA board to simulate user use, keep it working and observe whether there are any failures. After the burn-in test, electronic products can be sold in batches.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn