About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-08-27 11:55:13

date:2019-08-27 11:55:13

PCBA manufacturers four major production processes Introduction

PCBA refers to the inserting and soldering process of mount the the components on PCB bare board. The production process of PCBA needs to go through a series of processes to complete the production. This article introduces the various processes of PCBA production.

The PCBA manufacturer's production process can be divided into several large processes, SMT chip processing → DIP plug-in processing → PCBA test → finished product assembly.

First, SMT processing links

1. According to the customer Gerber file and BOM list, make the SMT production technics file and generate the SMT coordinate file.

2. Check whether all the production materials are ready, make a complete set, and confirm the PMC plan for production.

3. Perform SMT programming and make the first-piece for verification to ensure correctness.

4. According to the SMT technics, make laser stencil

5. Solder paste printing to ensure uniform solder paste, good thickness and consistency

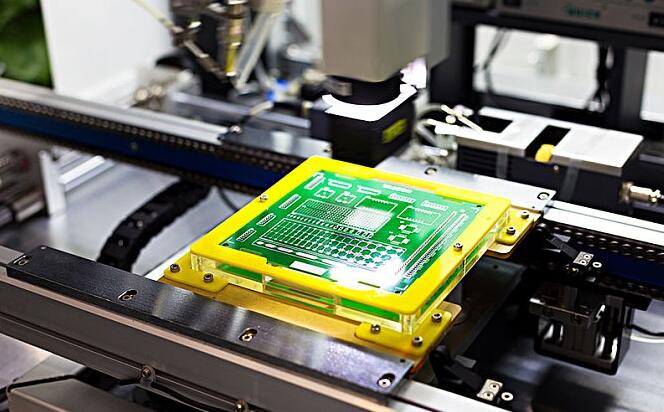

6. Mount the components on the circuit board through the SMT placement machine, and perform online AOI automatic optical inspection if necessary.

7. Set the perfect reflow soldering furnace temperature curve, let the circuit board flow through reflow soldering, solder paste from paste, liquid to solid state, after cooling, good welding can be achieved.

8. After the necessary IPQC check

9. The DIP plug-in technics passes the plug-in material through the board and then flows through the wave soldering for soldering.

10. Necessary post-furnace technics such as shearing, post-welding, board cleaning, etc.

11.QA conducts comprehensive testing to ensure quality is OK

Second, DIP plug-in processing links

The process of DIP plug-in processing is: plug-in → wave soldering → shearing → post-welding processing → washing board → quality inspection

1, The plugin

Processing the plug material pins and insert them on the PCB board.

2, Wave soldering

The inserted board is soldered by wave soldering. In this process, liquid tin is sprayed onto the PCB board, and finally cooled to complete the soldering.

3, Cut the feet

The pins of the soldered board are too long to be cut.

4, Post-welding processing

Manual soldering of components using an electric soldering iron.

5, Wash the board

After wave soldering, the board will be dirty, cleaned with wash water and wash tank, or machine cleaned.

6, Quality inspection

Pcb manufacturers inspect PCB boards, and unqualified products need to be repaired, and qualified products can enter the next process.

Third, PCBA test

PCBA tests is the most critical quality control process in the entire PCBA processing process. It is necessary to strictly follow the PCBA test standards and test the test points of the board according to the customer's test plan.

The PCBA test also includes five main forms: ICT test, FCT test, age test, fatigue test, and test in harsh environments.

The ICT (In Circuit Test) test mainly includes the on-off, voltage and current values and fluctuation curves, amplitude, noise, etc. of the circuit;

The FCT (Functional Circuit Test) test requires IC program programming, simulates the function of the entire PCBA board, finds problems in hardware and software, and equips with necessary production fixtures and test stands;

The aging test is mainly for the pcb manufacturer to energize the PCBA board and electronic products for a long time, keep their work and observe whether there is any failure. After the aging test, the electronic products can be sold in batches;

The fatigue test is mainly to sample the PCBA board, and perform high-frequency and long-term operation of the function to observe whether there is a failure. For example, if the mouse is continuously clicked for 100,000 times or the LED light is turned on and off 10,000 times, testing the probability of failure. Feedback on the performance of the PCBA board in the electronic product;

The test under the Severe Conditions is mainly to expose the PCBA board to the limit temperature, humidity, drop, splash, vibration, and obtain the test results of random samples to infer the reliability of the entire PCBA board batch product.

Fourth, the finished product assembly

The PCBA manufacturer will assembly the qualified PCBA board of the housing, then test it and finally ship it.

PCBA production is ring by ring, and any problem in one link will have a very large impact on the overall quality. PCBA manufacturers need to strictly control each process.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn