About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2018-11-08 11:30:00

date:2018-11-08 11:30:00

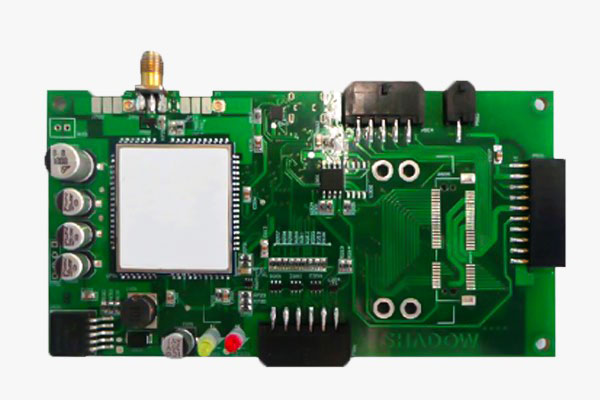

PCBA reliability test

After the PCBA reliability test, the component's high resistance value is abnormal, how to find the failure point?

The stress on the board of the computer analog component is normal, and the reliability of the PCBA is not enough. Is it a problem of matching components and plates? Or is the tolerance of the packaged solder balls insufficient?The so-called WLCSP wafer-level chip size package, the full name of Wafer Level Chip Scale Packaging, refers to the entire wafer-level packaging process after the completion of the cutting process, after cutting, the package size is equal to the original die size The subsequent use of the redistribution layer (RDL) can directly pull the I/O out of the array solder ball to the PCB.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn