About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-05-21 16:29:00

date:2019-05-21 16:29:00

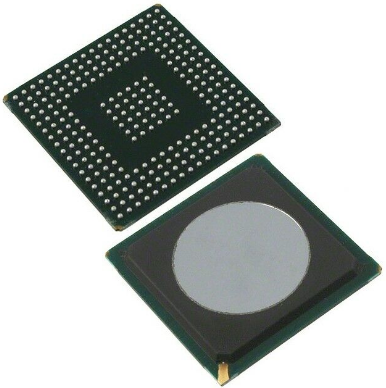

PCB assembly PBGA (CPU processor)

The Plastic BGA carrier is a common printed board substrate, generally a 2-4 layer organic material multilayer board. The chip is connected to the upper surface of the carrier by wire bonding, and the plastic film is formed on the surface of the carrier with eutectic solder ball array.

There is also CDPBGA (carity down PBGA), which refers to a chip area with a square depression in the center of the encapsulation, also known as a cavity area.

Disdvantage

The encapsulation cost is relatively low; compared with QFP, it is not easy to be mechanically lost; it is suitable for large-scale electronic assembly; the texture is the same as the PCB substrate, the thermal expansion coefficient is almost the same, when welding, the stress on the solder joint is small, and the solder joint is reliable. The impact on solder joint reliability is also less.

Disadvantage

Easy to absorb moisture.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn