About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2022-03-09 17:11:05

date:2022-03-09 17:11:05

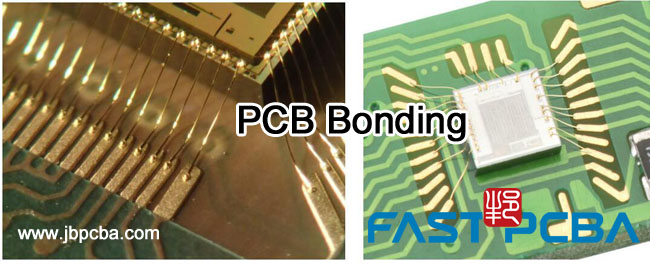

PCB bonding is a method of wire bonding in the chip production process. It is generally used to connect the internal circuit of the chip with gold wire or aluminum wire and the package pins or circuit board gold-plated copper foil before packaging. Ultrasonic waves from an ultrasonic generator (generally 40-140KHz), the high-frequency vibration is generated by the transducer, and transmitted to the riving knife through the horn. When the ribbing knife is in contact with the lead wire and the workpiece to be welded, under the action of pressure and vibration, the surfaces of the metals to be welded rub against each other , the oxide film is destroyed, and plastic deformation occurs, causing the two pure metal surfaces to be in close contact, achieving the combination of atomic distances, and finally forming a firm mechanical connection. Generally, after bonding (that is, after the circuit is connected to the pins), the chip is packaged with black glue.

The advantage of the PCB bonding packaging method is that the finished product is much higher than the traditional SMT patch method in terms of anti-corrosion, shock resistance and stability. At present, the widely used SMT technology is to solder the pins of the chip on the circuit board. This production process is not suitable for the processing of mobile storage products. There are problems such as virtual soldering, false soldering, and missing soldering in the packaging test. , In the process of daily use, due to the long-term exposure of the solder joints on the circuit board to natural and human factors such as moisture, static electricity, physical wear, and slight acid corrosion, the product is prone to short circuits, open circuits, and even burns. The bonding chip is to connect the internal circuit of the chip to the packaging pins of the circuit board through gold wires, and then cover it with organic materials with special protection functions to complete the post-package. The chip is completely protected by organic materials and is isolated from the outside world. There is no Moisture, static electricity and corrosion occur; at the same time, the organic material is melted at high temperature, covered on the chip, and then dried by the instrument.

PCB bonding process:

1. Cleaning the PCB

Scrub the oil, dust, and oxide layer on the circuit board position, and then use a brush to clean the wiping position, or blow it with an air gun.

2. Drip Adhesive

The amount of glue drops is moderate, the number of glue points is 4, and the four corners are evenly distributed; the bonding glue is strictly prohibited from contaminating the pad.

3. Die Attach (Solid Die)

When using a vacuum suction pen, the suction nozzle must be flat to avoid scratching the wafer surface. Check the orientation of the wafer, and it must be "smooth and positive" when sticking to the PCB: flat, the wafer and the PCB are closely attached in parallel with no voids; stable, the wafer and the PCB board are not easy to fall off during the entire process; positive, the wafer and the PCB are reserved in place Positive paste, can not be deflected, pay attention to the wafer direction should not be reversed phenomenon.

4. Bond Line

Bonding's PCB board has passed the bonding tensile test: 1.0 line is greater than or equal to 3.5G, 1.25 line is greater than or equal to 4.5G.

Standard aluminum wire with a fixed melting point: the wire tail is greater than or equal to 0.3 times the wire diameter, and less than or equal to 1.5 times the wire diameter. The shape of the aluminum wire solder joint is oval.

Solder joint length: greater than or equal to 1.5 times the wire diameter, less than or equal to 5.0 times the wire diameter.

The width of the solder joint: greater than or equal to 1.2 times the wire diameter, less than or equal to 3.0 times the wire diameter.

During the bonding process, it should be handled with care, and the point should be accurate. The operator should use a microscope to observe the bonding process to see if there are any bad phenomena such as broken bonding, winding, offset, hot and cold welding, and aluminum lifting. To notify the relevant technical personnel to solve in time.

Before the official production, there must be a first inspection by a special person to check whether there is a state error, a lack of state, a lack of state and other phenomena. In the production process, a special person must check its correctness at regular intervals (up to 2 hours).

5. Plastic Closures

Before installing the plastic ring on the chip, check the regularity of the plastic ring to ensure that the center of the plastic ring is square without obvious distortion. When installing, ensure that the bottom of the plastic ring is closely attached to the surface of the chip, and the photosensitive area in the center of the chip is not blocked. .

When dispensing, the black glue should completely cover the sun circle of the PCB board and the aluminum wire of the bonding chip, and it should not be exposed, and the black glue should not seal the PCB sun circle. into the wafer.

During the dispensing process, the needle tip or swab should not touch the surface of the wafer in the plastic ring and the bonding wire.

The drying temperature is strictly controlled: the preheating temperature is 120±5 degrees Celsius, and the time is 1.5-3.0 minutes; the drying temperature is 140±5 degrees Celsius, and the time is 40-60 minutes.

The surface of the black glue after drying shall not have pores or uncured appearance, and the height of the black glue shall not be higher than the plastic ring.

6. Test

A combination of multiple testing methods:

A. Manual visual inspection;

B. Bonding machine automatic welding wire quality inspection;

C. Automatic Optical Image Analysis (AOI) X-ray analysis to check the quality of inner solder joints.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn