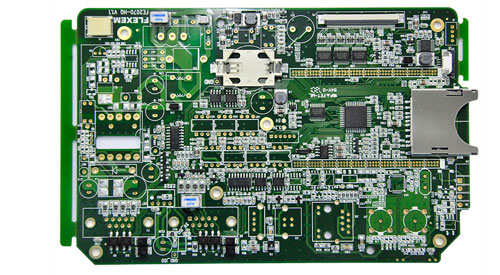

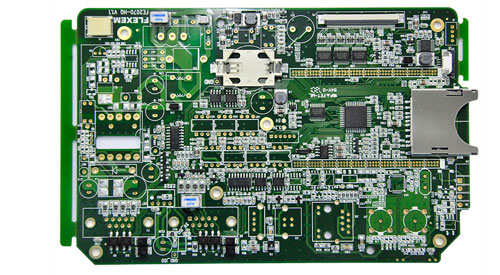

Pcb etching

date:2018-11-16 16:58:00

date:2018-11-16 16:58:00

Weigh out the appropriate amount of ferric chloride block, and then arrange the etching solution according to the ratio of ferric chloride block: water of about 3:1.

Be sure to note that ferric chloride is corrosive. It is strictly forbidden to grab it directly by hand. The tweezers used for clamping should also be cleaned in time. If you accidentally get into the eyes, please wash with plenty of water immediately and find a doctor as soon as possible! Then throw the ferric chloride block into the water and watch it in a few minutes. It dissolves very slowly...

When the solution is brown and there is no solid, it means the etchant is already configured!

Note: Make sure there are no impurities in the etchant! The most intolerable impurity in the etching solution is grease! Put a few nails in the water to speed up the etching, try?

Put the photosensitive plate slowly into the etching solution (in fact, the circuit should float down on the liquid surface, but because the board area is not enough, it only sinks to the bottom...) Do not use the basin during the process, and do not use any Things to touch the board! Otherwise the consequences will be very serious!

After an hour, let's see it (it's too long? Increase the concentration of the etchant!), then use a plastic bag as a glove, take the board out carefully (be careful not to touch the line!), observe the non-line part Is there no metal color? If there is still, continue to soak for half an hour and then come to see it~ If you are not sure, you can use a multimeter to measure the resistance of the non-circuit part as shown below. If the resistance is infinite, then it will be fine! If you are measuring this way, congratulations, your first photosensitive board has been successfully produced.

FASTPCBA 20 years' experience for PCB Assembly.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2018-11-16 16:58:00

date:2018-11-16 16:58:00

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn