About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-08-15 14:38:35

date:2019-08-15 14:38:35

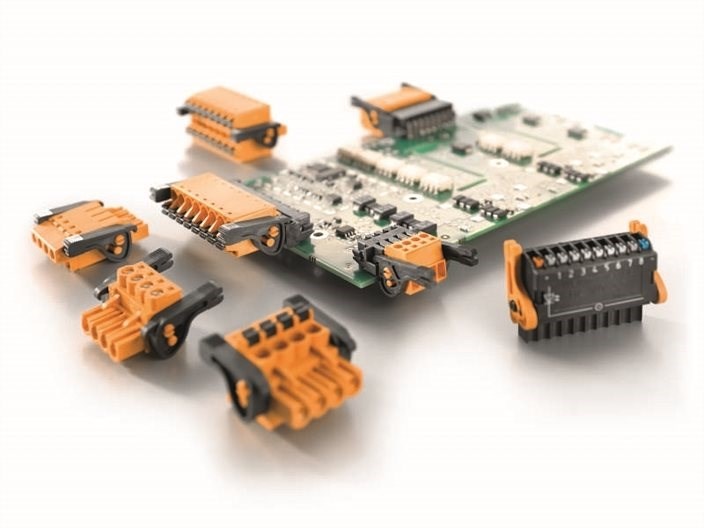

Pcb manufacturer china design connector four key elements

Generally, for pcb manufacturer china, solder does not provide high-quality mechanical support. The soldering strength of the plug-in solder itself is much strong than that of surface mounting. One is because the plug-in solder has a large cross-sectional area; the other is because the lead is inserted into the through-hole to provide mechanical support.

Usually caused by the connector, there are thermal shock during the initial welding process, temperature cycling during operation, insertion force, twisting force and vibration force.

There are four key elements for pcb manufacturer china in designing connectors: lead structures, molding compounds, mechanical supports, and lead metal.

(1) Lead structure. The most important feature of the connector leads is their flexibility. Obviously, the flexible lead not only compensates for the coefficient of thermal expansion between the connector and the board, but also cushions the insertion stress. Both gull-wing and J-shaped pins are available. However, because the J-shaped pin structure bends the lead under the component body, such a connection point is difficult to visually measure. Currently, for pcb manufacturer china only a few connectors adopt this structure.

(2) Molding compound. Conventional thermoplastic materials have a lower melting point and are not suitable for surface assembly and reflow technics. High-temperature thermoplastic materials are suitable, but their high melting point increases pcb manufacturer china technics difficulty and cost.

(3) Mechanical support. Except in a few cases, the connector should not regard welding as the only mechanical support, but a variety of auxiliary support methods can be used. The connector can be mounted on the board by riveting, crimping, routing or screwing.

(4) Lead metal. In order to ensure sufficient soldering strength, the plating metal of the connector leads must have high solderability. Poor weldability not only causes pcb manufacturer china problems during the production process, but also reduces the welding strength. The eutectic Sn-Pb coating provides the highest solderability, while the other coatings are similar.

Currently, a variety of surface assembled connectors are available on the market.

The above is pcb manufacturer china to share the four key elements of smt connector knowledge, if you need more information, please pay attention to our official website:http://www.jbpcba.com

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn