About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-10-18 17:19:21

date:2019-10-18 17:19:21

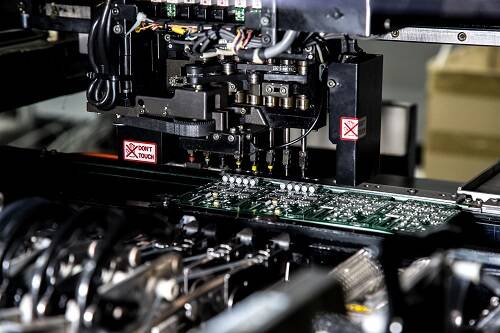

PCB manufacturer placement machine speed

The placement speed determines the production capacity of the placement machine and the pcb manufacturer production line, which is an important limiting factor for the production capacity of the entire line. The placement speed is generally described by the following parameters.

1. Mounting cycle. The placement cycle is the most basic parameter for marking the placement speed. It refers to the time taken from the time the component is picked up, after being tested and placed on the PCB and then returned to the position of the pickup component. Each time this trip is performed, a placement operation cycle is completed. Generally, the mounting cycle of high-speed machine-mounted Chip components is less than 0.2s, and the current maximum mounting cycle is 0.06-0.03s; the general-purpose machine-mounted QFP has a mounting cycle of 1-2s, and the placement of Chip components mounting period is 0.3~0.65s.

2. Mounting rate. The Mounting rate refers to the number of components placed in 1h, and the unit is c/h. It is the placement speed measured by the placement machine manufacturer under ideal conditions. The calculation of the theoretical speed does not take into account the PCB loading and unloading time, the closest the patch distance with small number of components (about 150 chip components), and then calculate the time taken to mount one component, and calculate the mounting number of 1h .

However, the pcb manufacturer should consider the following auxiliary time in actual production.

a. PCB loading/unloading time, usually 5-10s for the placement machine

b. Large (rectangular) PCB components are far apart and the patching time will be extended.

c. Refueling time.

d. Machine repair time (days/months).

e, unpredictable downtime

In short, the actual placement speed is much lower than the theoretical placement speed, usually 65%-70% of the theoretical placement speed.

3. The adaptability of the placement machine. The adaptability of the placement machine refers to the ability of the placement machine to adapt to different placement requirements, including the type of components, the number and type of feeders, and the adjustability of the placement machine. When the type of printed circuit board is changed, the pcb manufacturer needs to adjust the placement machine, including the reprogramming of the placement machine, the replacement of the feeder, the transfer mechanism of the printed circuit board, and the adjustment of the workbench. Adjustment and replacement of the placement head.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn