About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-10-15 16:52:05

date:2019-10-15 16:52:05

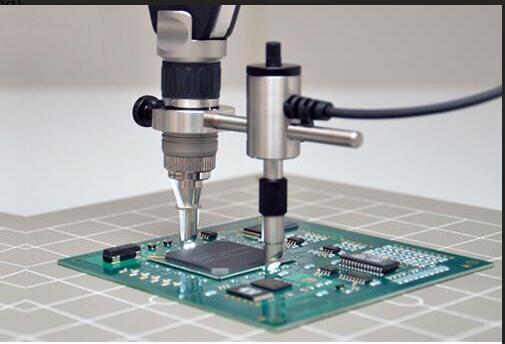

Pcb production X-ray inspection process

1. Preparation

A. Check the machine and confirm that the front and rear doors are completely closed.

B.Be careful not to put your hand on the door shaft to prevent crushing during opening and closing the rear door, .

C. Be light when opening and closing the door, avoid collision and damage the internal mechanism, prohibit the operation of non-operator

2. Turn on

A. Turn on the power

After the vacuum of the machine reaches the standard of usage (the vacuum status indicator turns green), the power is turned on for the machine to warm up.

3. Load the pcb production circuit board sample

A. Load the sample to be tested

B. The height of the pcb production sample can not exceed 50mm

4. Scan and adjust the image

A. After the x-ray is turned on, until the x-ray power to rise to the setting value and stabilize before starting the testing board scan.

B. Do not turn off the X-ray application soft immediately after the machine has finished initializing the settings. Do not switch the switch key to Power On, and do not do the Initialization twice.

5. Save the image file

A. Save or print the desired image file

B. Move the inspection site or replace the pcb production template for testing. Just need to repeat the above steps.

6. Turn off the power

A. When closing the application program, click the close button and wait for the program to close completely. Do not click the close button again.

B. After the test is completed, turn off all power

C. In an emergency, the emergency switch should be pressed in tim

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn