About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-11-04 15:45:12

date:2019-11-04 15:45:12

Pcb supplier reflow solder ball generation cause and solution

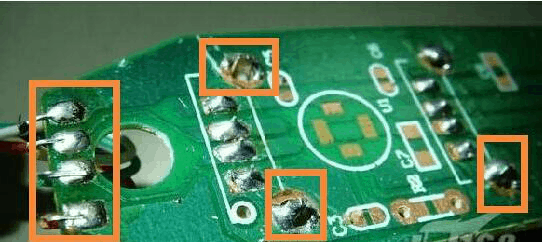

Spherical tin particles with a diameter greater than 0.13 mm or within 0.13 mm of the wire are collectively referred to as solder balls. The appearance of solder balls violates the principle of minimum gap and affects the electrical reliability of the assembled board.

In pcb supplier circuit board manufacturing, the generation of solder balls is closely linked to the soldering process of solder joints. If the gas in the solder joint does not escape in time, it may cause voiding. If the escape speed is too fast, the solder alloy will adhere to the solder mask to produce a solder ball. The surface of the solder joint has solidified and the inside is still in the liquid stage. The gas that is escaped may produce pinholes.

Reasons for producing a solder ball:

1) The board contains too much water.

2) The solder mask is not treated well by the pcb supplier, and the adsorption of the solder mask is a very important cause of the solder ball.

3) The amount of flux used is too much.

4) The preheating temperature is not enough, and the flux is not effectively volatilized.

5) The solder paste particles adhered to the board during printing tend to cause solder ball phenomenon.

Measures to prevent solder balls are as below:

1) Design the pads properly.

2) The through-hole copper layer is at least 25um thick to avoid the influence of water vapor in the printed circuit board.

3) Use a suitable flux coating method to reduce the amount of gas mixed in the flux.

4) Properly increase the preheating temperature.

5) Pre-weld baking of the printed circuit board.

6) The pcb supplier uses a suitable solder mask. Relatively speaking, the flat solder mask surface is more prone to solder ball phenomenon.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn