About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-10-14 15:05:46

date:2019-10-14 15:05:46

Pcb testing circuit board factory AOI working principle

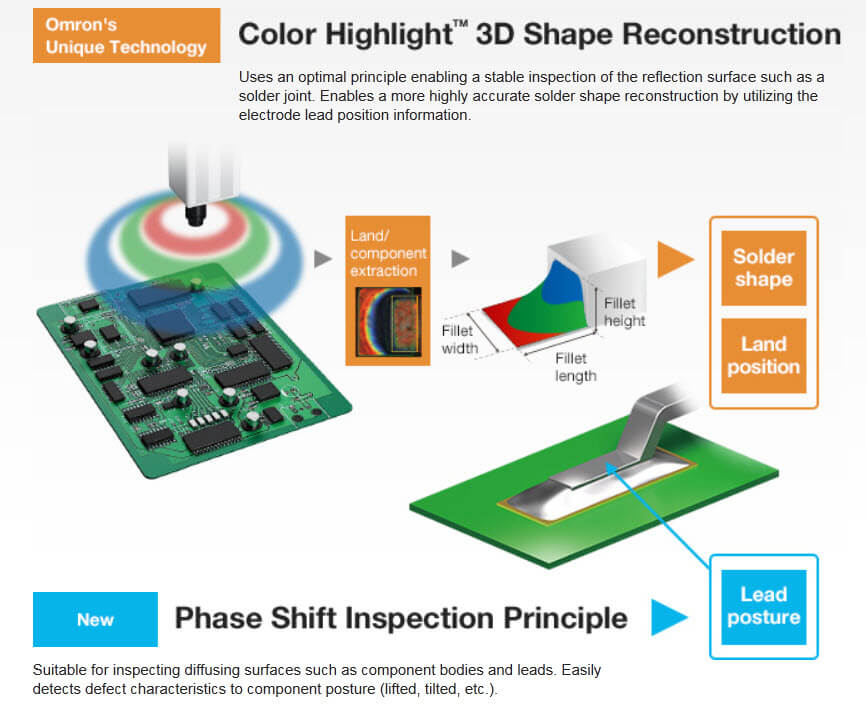

The basic principle of AOI detection is to compare, analyze and judge the reflected amount of the light source with the programmed standard by illuminating the measured object with artificial light source, LED light, optical lens and CCD.

1. Two-dimensional AOI adopts vertical camera, and realizes the discrimination of PCB solder joint quality by color high-brightness method. When the machine is working, red, green and blue three-section circular illumination are irradiated at different heights on the circuit board. The color camera is mounted vertically on the centerline of the ring illumination to extract the board image.

Since the red light is located farther from the high substrate surface (higher position) than the other two kinds of light, the incident angle with respect to the substrate surface is large, and the light that strikes the surface of the flat object is reflected toward the camera directly above, and is irradiated. The light on the solder surface is not reflected directly above. Therefore, for a flat surface portion, the camera captures a red area. The principle is the same as the red light, the green area is the slightly inclined solder surface captured by the camera, and the blue area is the steeply inclined solder surface captured by the camera. In this way, the shape of the three-dimensional solder joint can be converted into a two-dimensional color image through the color brightness mode, so that the quality of the solder joint can be further detected by image processing combined with a certain mathematical model.

2. Three-dimensional A01 adds an angle camera head while using a vertical camera. When the vertical camera looks from top to bottom, the angle camera observes the solder joint image from the side, just like the manual visual inspection. In order to see the local details, it is often necessary to adjust the light and the observation angle. Therefore, the three-dimensional AOI has a stronger fault detection capability. For example, when detecting the welding quality of the PLCC device, the advantages of the three-dimensional AOI can be fully manifested. The illumination system in the three-dimensional AOI adopts an independently controllable LED array as a light source, and the light-emitting diode the root canals are arranged in a precise annular array, all focused on the field of view. The closer to the inner ring, the closer the vertical angle is to the vertical angle. The closer the angle is to the outer ring, the more oblique the angle is, and the diodes can be programmed to control the optimal Illumination texture, angle, direction and density; adjusts the angle, direction and brightness of the illumination for each inspection image to meet the unique requirements of any PCB testing.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn