About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-05-11 14:35:00

date:2019-05-11 14:35:00

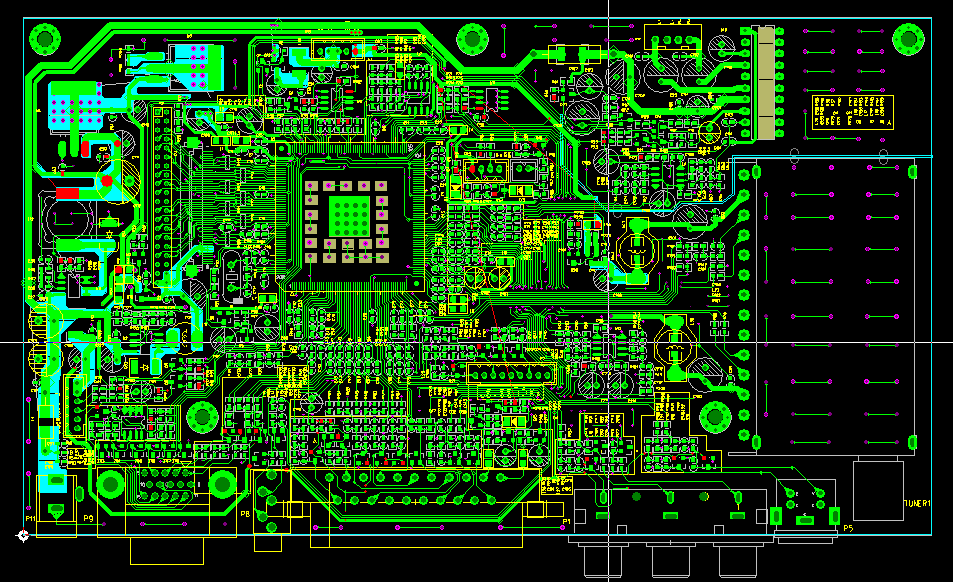

Printed circuit board copy board method and steps

The first step is when you get a PCB, record the model, parameters, and position of all the components on the paper, especially the direction of the diode, the three tubes, and the direction of the IC notch. It is best to take two photo of components positions with a digital camera.

In the second step, all devices are removed and the tin in the PAD hole is removed. Clean the PCB with alcohol and put it into the scanner. When scanning the scanner, you need to raise some scanned pixels slightly to get a clearer image. Start POHTOSHOP, scan the silkscreen surface in color, and save the file. And print it out for later use.

In the third step, the two layers of TOP LAYER and BOTTOM LAYER are slightly polished with water-dyed paper, polished to a copper film, placed in a scanner, and the PHOTOSHOP is started, and the two layers are separately scanned in color. Note that the PCB must be placed horizontally in the scanner, otherwise the scanned image will not be available, and save the file.

The fourth step is to adjust the contrast and brightness of the canvas so that the portion with the copper film and the portion without the copper film are strongly contrasted, then turn the secondary image to black and white to check whether the line is clear. If it is not clear, repeat this step. If it is clear, save the image as black and white BMP format files TOP.BMP and BOT.BMP. If you find that there is a problem with the graphics, you can use PHOTOSHOP to fix and correct it.

The fifth step is to convert the two BMP files into PROTEL format files, and transfer them into two layers in PROTEL. If the two layers of PAD and VIA are basically coincident, it indicates that the first few steps are very good. If there is a deviation, repeat the third step.

Sixth, convert the BMP of the TOP layer to TOP.PCB, pay attention to the layer that is converted to the SILK layer, which is the yellow layer, then you can trace the line in the TOP layer, and place the device according to the drawing in the second step. Remove the SILK layer after painting.

Seventh, the TOP.PCB and BOT.PCB are transferred in PROTEL, and it is OK to combine them into one figure.

In the 8th step, use the laser printer to print the TOP LAYER and BOTTOM LAYER on the transparencies (1:1 ratio), put the film on the PCB, and compare whether there is any error. If it is correct, you are done.

Others: If it is a multi-layer board, it should be carefully polished to the inner layer, and repeat the steps from the third to the eighth. Of course, the naming of the graphics is different. According to the number of layers, the general double-panel copy board is more than multiple layers. The board is much simpler, and the multi-layer board is prone to misalignment, so the board is particularly careful (internal vias and non-vias are prone to problems).

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn