About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-10-28 10:33:10

date:2019-10-28 10:33:10

Printed circuit board manufacturers reflow soldering poor wetting solution

The welding quality of components' solder joints is a key factor that directly affects the quality of printed circuit components and even the whole machine.It is affected by many parameters, such as solder paste, substrate, components weldability, silkscreen printing, mounting accuracy and welding process.The possible defects in reflow welding process mainly include poor wetting, bridging, tombstone, tin ball and deviation of components, etc. Printed circuit board manufacturers introduce the causes and solutions of poor wetting in reflow soldering as below.

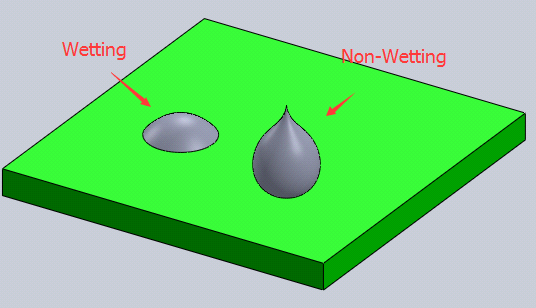

1. Poor wetting

Poor wettability refers to the solder solder alloy is not well spread out, so can not get a good solder, which directly affects the reliability of solder

2. Causes of poor wetting of solder joints:

A. The coating on the surface of the pad or pin is oxidized, and the presence of the oxide layer prevents contact between the solder and the coating.

B. Insufficient coating thickness or poor processing, which is easy to be damaged during assembly.

C. Insufficient welding temperature.Compared with SnPb, the melting point of the commonly used lead-free solder alloys increases and the wettability decreases greatly, so higher welding temperature is needed to ensure the welding quality.

D.Low preheating temperature or insufficient flux activity make the flux unable to effectively remove oxide film on the surface of solder pad and pin.

E. Mismatches between coating and solder may also result in poor wetting.

F. Components are getting smaller and smaller, and the amount of solder paste printed is less, so the flux in the solder paste volatilizes rapidly under the original temperature curve, which affects the wettability of the solder paste

G. Contaminated solder or flux.

3. Measures to prevent poor wetting are as follows:

A. Printed circuit board manufacturers store substrate and components as required and do not use deteriorated welding materials.

B. Select substrate with qualified coating quality.Typically, a coating at least 5 μm thick is required to keep the material fresh for 12 months.

C. The components of brass pins shall be plated with a coating of 1~3 μm before welding, otherwise the Zn in the brass coating will affect the welding quality.

D. Printed circuit board manufacturers reasonably set up welding process parameters and increase the preheating or welding temperature appropriately to ensure sufficient welding time.

E. The wetting behavior of all kinds of solder can be significantly improved in nitrogen protection environment

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn