About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-10-23 14:36:39

date:2019-10-23 14:36:39

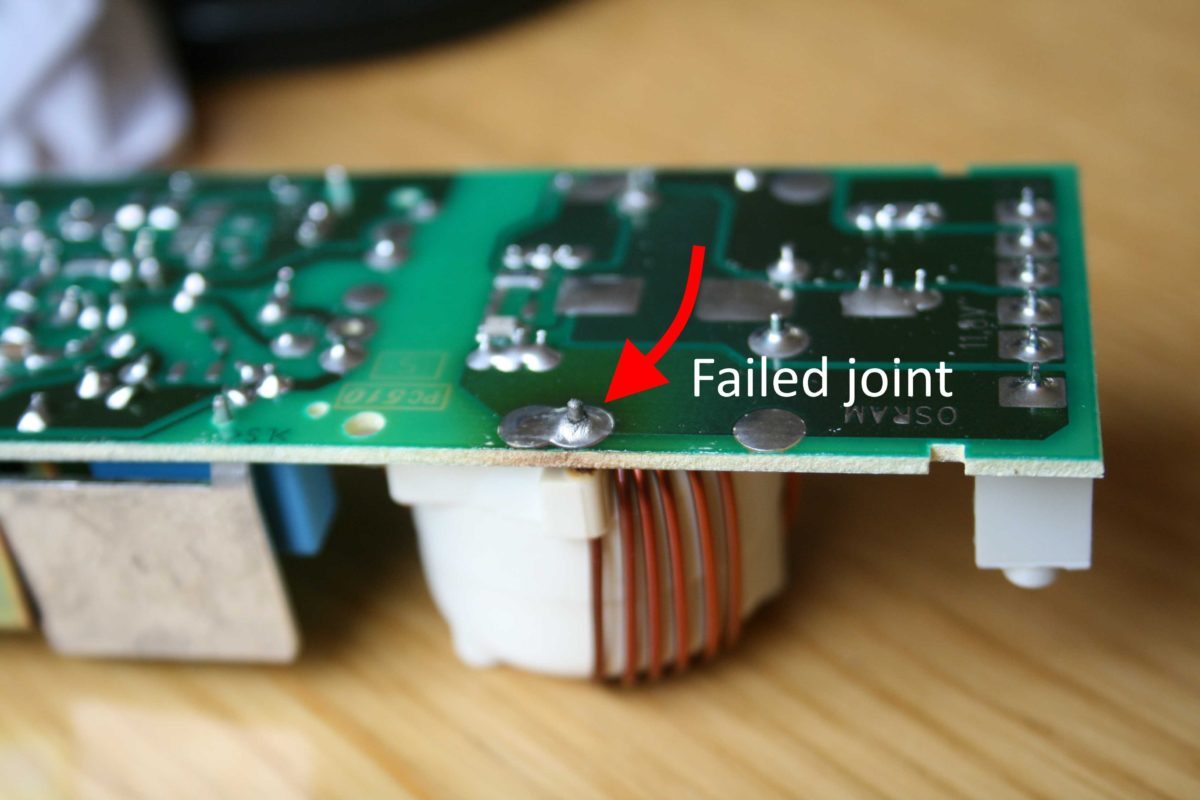

Prototype pcb manufacturing complete solder joint requirements

1.Assembly reliability

Assembly reliability means manufacturing products with high reliability. For PCBA, including:

Obtain a complete solder joint;

Prototype pcb manufacturing solder joint failure is not caused during assembly.

2.Complete solder joints

The so-called complete solder joint refers to the solder joint that meets the acceptance conditions of IPC-A-610. This is the goal of manufacturing and the basic requirement for obtaining solder joint reliability. The complete solder joints largely determine the inherent reliability of the prototype pcb manufacturing solder joint.

3. Common incomplete solder joints

Common incomplete solder joints include but are not limited to:

(1) Solder Mask Definition Pads (although they are common designs, they are very risky for BGA).

(2) No IMC continuous layer solder joints.

(3) Cold solder joints.

(4) Solder joints of ENIG coatings (high-risk solder joints - there may be problems with black, gold, and Ni oxide pads).

(5) Tin solder joints.

(6) Ball joints.

(7) Hot air remelting rework solder joints.

(8) flux does not completely evaporate solder joints

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn