About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2020-11-03 09:51:26

date:2020-11-03 09:51:26

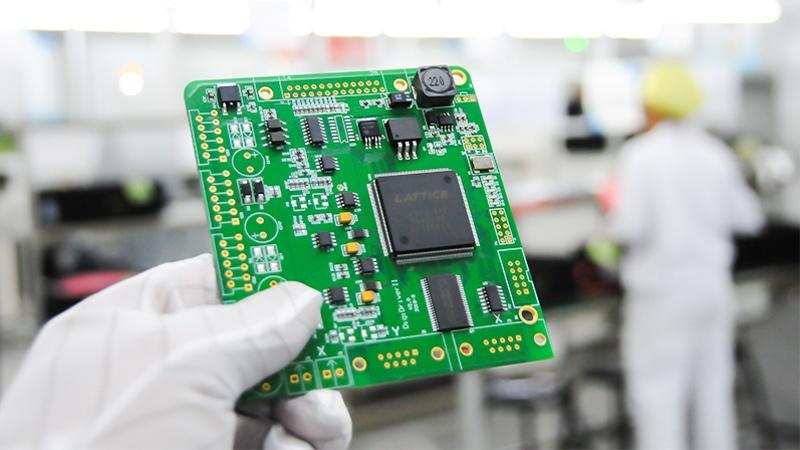

What is smt assembly meaning? SMT is called Surface Mount or Surface Mount Technology. It is the most popular technology and craft in the electronics assembly industry.

It is a kind of leadless or short lead surface assembly components (SMC/SMD for short) mounted on the surface of a Printed Circuit Board (PCB) or other substrates, through reflow soldering or dip soldering, etc. Method to weld the circuit assembly technology.

SMT Assembly Process Composition

1. Printing

(Red Glue/Solder Paste) --> Inspection (AOI automatic or visual inspection is optional) --> Mounting (small devices first, then large devices: divided into high-speed placement and integrated circuit placement) --> Inspection (optional AOI optical/visual inspection) --> welding (using hot air reflow soldering for soldering) --> inspection (can be divided into AOI optical inspection appearance and functional test inspection) --> maintenance (tool: soldering station And hot-air desoldering station, etc.)--> board splitting (cutting board manually or with a splitting machine)

2. Solder paste printing

Its function is to print the solder paste on the PCB pads with a scraper at a 45-degree angle to prepare for the soldering of the components. The equipment used is a printing machine (a solder paste printing machine), located at the forefront of the SMT production line.

3. Parts placement

Its function is to accurately install the surface mount components to the fixed position of the PCB. The equipment used is a placement machine, which is located behind the printing machine in the SMT production line. Generally, high-speed machines and general-purpose machines are used in combination according to production requirements.

4. Reflow soldering

Its function is to melt the solder paste, so that the surface mount components and the PCB are firmly welded together. The equipment used is a reflow oven, which is located behind the placement machine in the SMT production line. The temperature requirements are quite strict and need to be measured in real time. The measured temperature is reflected in the form of a profile.

5. AOI optical inspection

Its function is to inspect the welding quality of the welded PCB. The equipment used is an automatic optical inspection machine (AOI), and the location can be configured in a suitable place on the production line according to the needs of inspection. Some are before reflow soldering, and some are after reflow soldering.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn