About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2018-10-31 14:17:00

date:2018-10-31 14:17:00

The process flow of PCBA

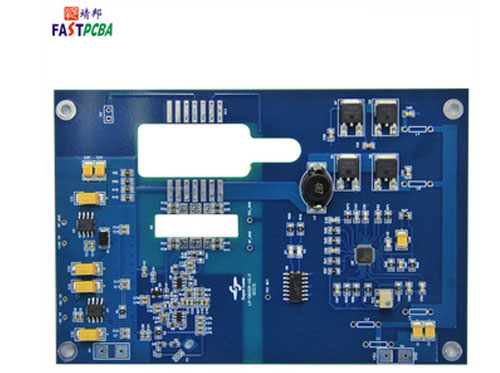

The process flow of PCBA processing is very complicated, including PCB board process, component procurement and inspection, SMT patch assembly, DIP plug-in, PCBA test and many other important processes. PCBA testing is the most critical quality control process in the entire PCBA processing process, which determines the final performance of the product.

1. The ICT test mainly includes the circuit's on/off, voltage and current values and fluctuation curves, amplitude, and noise.

2. FCT test requires IC program firing, simulates the function of the entire PCBA board, finds problems in hardware and software, and equips with necessary chip processing to produce fixtures and test stands.

3. The fatigue test is mainly to sample the PCBA board, and perform high-frequency and long-term operation of the function to observe whether there is a failure and judge the probability of the test failure, so as to feedback the working performance of the PCBA board in the electronic product.

4. In the harsh environment, the test is mainly to expose the PCBA board to the limit temperature, humidity, drop, splashing water and vibration, and obtain the test result of the random sample, so as to infer the reliability of the entire PCBA board batch product.

4: Special function test (different board requirements are inconsistent) - if you have infrared, you need an external receiver

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn