About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2021-01-28 13:52:50

date:2021-01-28 13:52:50

Through hole assembly refers to the process of soldering through-hole components to the bare board by wave soldering or manual soldering, and the component leads are drilled through the PCB board.

• Application of Through hole assembly

Through-hole components (THC) are suitable for high-reliability product layers that require stronger bonding because they can withstand higher environmental pressure, and the wires pass through the board holes. This is the wide application of THT that may suffer from military and aerospace The main cause of the product is from extreme acceleration, collision or high temperature. In addition, through-hole technology is also popular for testing and prototypes, sometimes requiring manual adjustment and replacement.

•Through Hole Components

There are two types of through-hole components: axial lead components and radial lead components. The axial lead element contains a straight line with its terminal passing through the element. In the THA process, the two ends of the lead pass through a hole on the circuit board, making the component closer to the circuit board and flatter. The figure below shows a typical axial lead component.

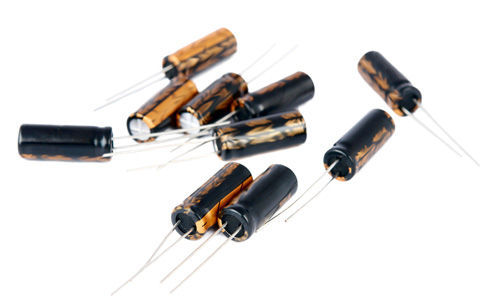

However, the radial lead element includes leads protruding from the element body. The figure below shows a typical radial lead assembly.

According to the above figure, it is easy to understand the difference between the axial lead element and the radial lead element. The former represents a flexible distance between two leads, while the latter represents a fixed distance. In addition, compared with the axial lead elements, the radial lead elements will be located above the circuit board, resulting in less space on the board.

• Advantages and disadvantages of Through hole assembly

Through hole assembly has stronger mechanical bonding force and is suitable for products that are prepared to withstand mechanical stress. In addition, Through hole assembly is easy to manually adjust and replace, and is widely recognized through testing and prototyping.

Because the through-hole component leads through the holes on the board is very time-consuming and leads to higher costs. Through hole assembly also limits the wiring space of multilayer PCBs, because the holes must cover all layers of the circuit board.

When it comes to Through hole assembly, wave soldering or manual soldering, reliability and repeatability will all be challenged by reduced manufacturing efficiency.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn