About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2019-08-05 11:24:28

date:2019-08-05 11:24:28

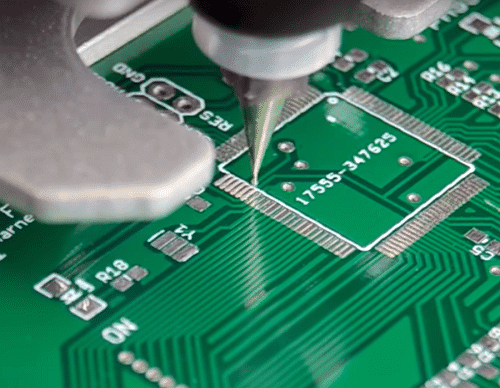

Turnkey pcb manufacturing common poor printing analysis and solutions

1,The printing position is deviated

Cause: The poor alignment of the stencil and the PCB is the main reason, and there are cases where the stencil is poorly produced; the printing machine is not accurate enough during the turnkey pcb manufacturing process.

Hazard: Easy to cause bridging connection.

Countermeasure:: adjust the stencil position; adjust the printing machine.

2,Insufficient filling

Insufficient filling is phenomenon in which the amount of solder paste supplied to the PCB pad is insufficient. Unfilled, lack of soldering, less soldering, dents, etc. all belong to insufficient phenomenon. Because the insufficient filling amount is related to various factors such as printing pressure, scrapper speed, off-grid conditions, solder paste performance and state, stencil manufacturing method, and poor stencil cleaning, it is very important to optimize the printing conditions during the turnkey pcb manufacturing process.

3, Penetration

Penetration refers to the phenomenon that flux penetrates around the pad being filled. The reasons for the infiltration are excessive pressure of the printing scrapper, excessive gap between the stencil and the PCB, etc. Measures such as adjusting the printing parameters and cleaning the stencil in time should be taken.

4, Bridge connection

Bridging connection is the phenomenon in which solder paste is printed onto adjacent pads. Possible reasons are the positional deviation of the stencil and the PCB, the printing pressure is large, the printing gap is large, and the reverse side of the stencil is not clean. In the turnkey pcb manufacturing process, the printing parameters should be adjusted properly and the template should be cleaned in time.

5, The solder paste pattern has depression

Cause: The blade pressure is too large; the hardness of the scrapper is not enough; the stencil window is too large.

Hazard: The amount of solder is not enough, it is easy to appear solder joint, and the solder joint strength is not enough.

Countermeasure: Adjust the printing pressure during turnkey pcb manufacturing; replace with metal scraper; improve stencil window design.

6,Too much solder paste

Cause: The stencil window size is too large; the gap between the stencil and the PCB is too large.

Hazard: Easy to cause bridging.

Countermeasure: Check the size of the stencil window; adjust the printing parameters, especially the gap of the PCB template.

7, The amount of solder paste is uneven, there are breakpoints

Cause: The stencil window wall is not smooth; the number of times of printing is too much, and the residual solder paste is not wiped off in time; solder paste thixotropy is bad.

Hazard: It is easy to cause insufficient solder, such as solder joints and defects.

Countermeasure:Wipe the stencil during turnkey pcb manufacturing.

8, Graphics contamination

Cause: The times of stencil printing is too many, and it cannot be wiped clean in time; the quality of solder paste is poor; there is jitter on the off-grid.

Hazard: Easy to cause bridging connection.

Countermeasure: Scrub the stencil; change the solder paste; adjust the machine.

In short, pcb manufacturer should pay attention to the parameters of the solder paste which will change at any time during solder paste printing , such as particle size , shape, thixotropy, flux performance, etc. In addition, the parameters of the printing machine will also cause changes, such as printing pressure, speed, environment temperature and so on. Solder paste printing quality has a great influence on the quality of the soldering. Therefore, in the turnkey pcb manufacturing process, each parameter in the printing process should be carefully treated by pcb manufacturer, and the relevant data should be observed and recorded frequently.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn