What are the causes of poor PCBA patch?

date:2020-08-31 15:22:32

date:2020-08-31 15:22:32

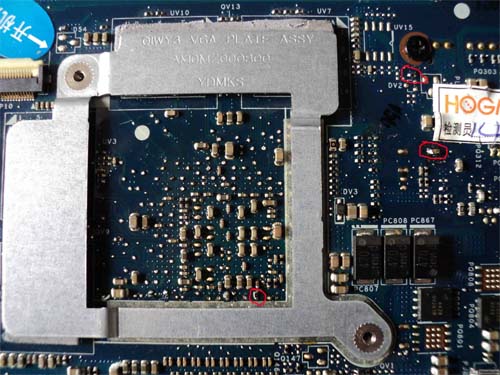

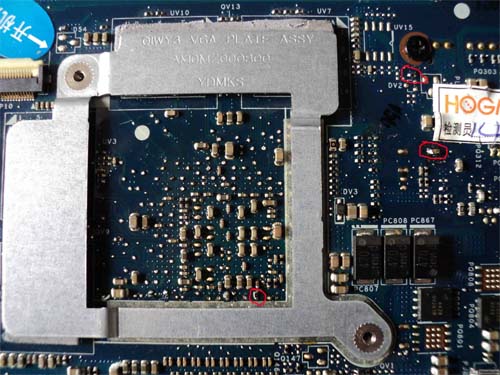

In the production process of PCBA patch, due to the influence of operation errors, it is easy to cause the defects of PCBA patch, such as: empty welding, short circuit, warping, missing parts, solder bead, warping foot, floating height, wrong parts, cold welding, Reverse, reverse / reverse, offset, component damage, less tin, more tin, gold finger sticking tin, overflow, etc., these defects need to be analyzed and improved to improve the product quality.

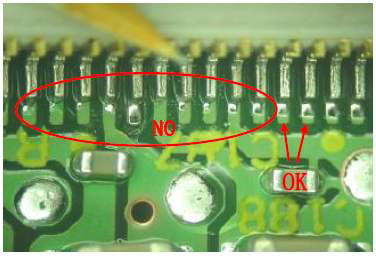

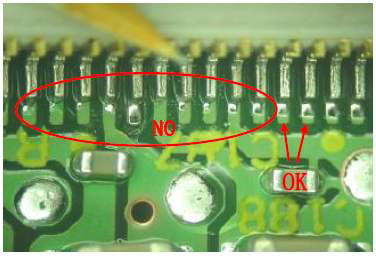

1. Missing Solder

The activity of solder paste is weak;

The opening of steel mesh is poor;

The distance between copper and platinum is too large or the copper pastes small components;

The pressure of scraper is too high;

Poor flatness of component foot (warping, deformation)

The preheating zone of reflow furnace heats up too fast;

PCB copper and platinum are too dirty or oxidized;

PCB board contains moisture;

Machine mounting offset;

Solder paste printing offset;

The machine splint track is loose, resulting in mounting deviation;

Mark point misillumination causes component deviation, resulting in missing solder;

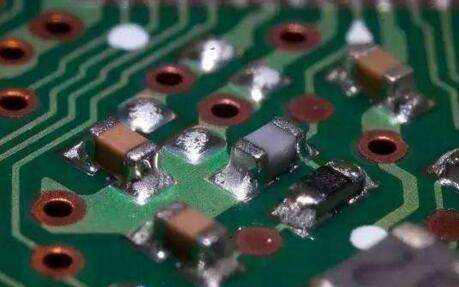

2. Short Circuit

The too large space between the steel mesh and the PCB board leads to the short circuit of solder paste printing too thick;

If the mounting height of components is too low, the solder paste will be squeezed to cause short circuit;

The temperature of reflow furnace is too fast;

Component mounting offset caused by;

The opening of steel mesh is poor (thickness is too thick, pin opening is too long, and opening is too large);

Solder paste cannot bear the weight of components;

The solder paste printing is too thick due to the deformation of steel mesh or scraper;

The activity of solder paste is strong;

The paste printing of peripheral components is too thick due to the roll up of the sealing adhesive paper at the blank point;

The vibration of reflow soldering is too large or not horizontal;

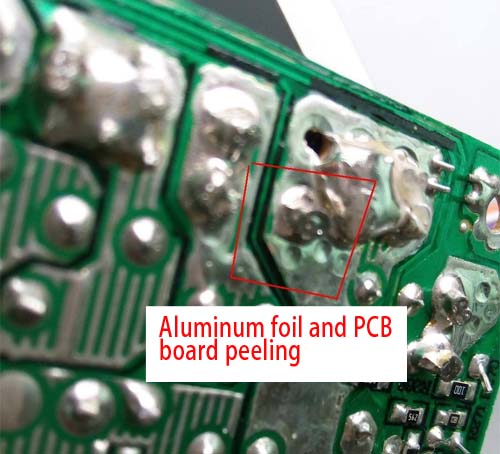

3. Irregularity

Different sizes of copper and platinum lead to uneven tension;

The heating rate is too fast;

Machine mounting offset;

Uneven printing thickness of solder paste;

The temperature distribution in the reflow furnace is uneven;

Solder paste printing offset;

The machine track splint is not tight, resulting in mounting deviation;

Machine head shaking;

The activity of solder paste is too strong;

Improper furnace temperature setting;

The distance between copper and platinum is too large;

Mark point wrong light causes yuan Youyang's deviation

4. Missing parts

The carbon sheet of vacuum pump is poor, and the vacuum is not enough, resulting in missing parts;

The suction nozzle is blocked or poor;

The thickness of components is not detected properly or the detector is poor;

Improper mounting height setting;

Excessive or no blowing at suction nozzle;

Improper vacuum setting of suction nozzle (applicable to MPa);

The mounting speed of special-shaped components is too fast;

The head trachea was severely damaged;

The sealing ring of gas valve is worn;

There are foreign matters on the rail edge of the reflow furnace to wipe off the components on the board;

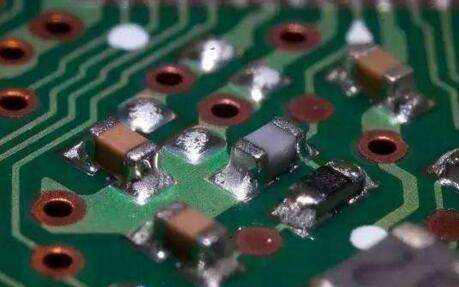

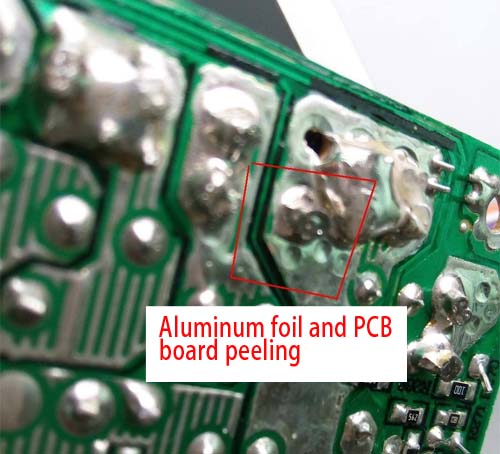

5. Solder pearl

Reflow soldering preheating is insufficient and heating is too fast;

The temperature of solder paste was not completely recovered after cold storage;

The solder paste is hygroscopically splashed (the indoor humidity is too heavy);

Too much moisture in PCB board;

Add excessive diluent;

Improper design of steel mesh opening;

Tin powder particles are uneven.

6. Deviation

The positioning reference point on the circuit board is not clear;

The positioning reference point on the circuit board is not aligned with the reference point of the screen board;

The fixed clamping of the circuit board in the printing machine is loose, and the positioning thimble is not in place;

Failure of the optical positioning system of the printing press;

The opening of solder paste leakage screen board does not conform to the design documents of circuit board.

In order to improve the defects of PCBA patch, it is necessary to strictly check every link to prevent the problems in the previous process from flowing to the next process as little as possible.

FASTPCBA 20 years' experience for PCB Assembly.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2020-08-31 15:22:32

date:2020-08-31 15:22:32

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn