About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

pcba13@fastpcba.cn

pcba13@fastpcba.cn

date:2021-07-10 10:10:20

date:2021-07-10 10:10:20

Cem-1 PCB material? It is so strange to most people, it is one of the substrates of printed circuit boards. It is low-grade in the PCB material industry and is only suitable for single-sided PCBs, but it is widely used.

Some people will say that technology is developing so fast now that every electronic device is becoming smaller and smaller. Why such low-grade materials can be widely used.

Yes, the technology is getting higher and higher, but the average time, components are also higher, and more functions are assembled, which will allow more designers to use single-sided PCB (Cem-1 material) to control costs.

Single-sided PCB (single-layer PCB) will greatly reduce the design cost, which is the most important reason.

Cem-1 material

He classified materials that meet CEM-1 specifications in the NEMA classification-a wide range of materials used for the production of up to 1-layer printed circuit boards.

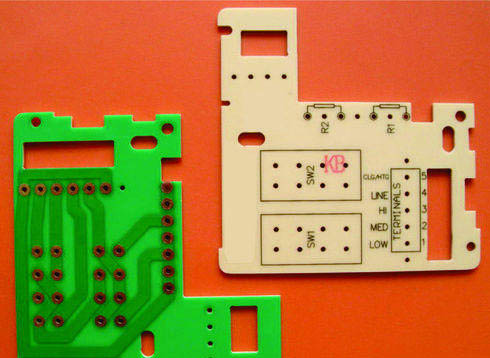

The standard CEM-1 material is a cellulose-based composite material with a layer of glass fiber laminate (FR-4) on the surface. Usually CEM-1 has a milky white color.

The feature of this material is that it is impossible to achieve metallization through holes, so this material can only be used to produce 1-layer printed circuit boards.

Standard CEM-1 meets the flammability class UL94-V0 as FR-4 material. Compared with FR-4, the mechanical properties of CEM-1 are slightly worse: CEM-1 is more fragile. The dielectric constant and dielectric loss tangent of the two materials are not much different.

Therefore, CEM-1 is a cheaper alternative to FR-4 material for the production of 1-layer printed circuit boards.

CEM-1 PCB material technical parameters

In the Cem PCB material series, there are other better CEM-3, let us look at the difference

CEM-1 and CEM -3

The glass fiber fabric surface and paper core composed of CEM-1 composite material are combined with epoxy resin. Mainly used in the printed circuit board industry. Compared with paper grades, it is easy to punch, has excellent electrical properties and higher bending strength. CEM-1 has excellent mechanical and electrical properties, with an impact force of 0.093".

CEM-3 is very similar to FR4. Instead of woven glass fabric, the "fly" type is used. CEM-3 is milky white and very smooth. It is a complete substitute for FR4 and has a very large market share in Asia. It is a flame-retardant epoxy copper clad laminate glass material, generally used in electronic products with double-sided and multi-layer PCB boards. CEM-3 is a new type of printed circuit substrate material developed based on FR-4. In recent years, CEM-3 has been used to replace FR-4 in Japan, even exceeding the dose of FR-4.

In the LED lighting market, most LED manufacturers use Cem1 as a basic material. It can strike the best balance between heat dissipation performance and PCB cost.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn