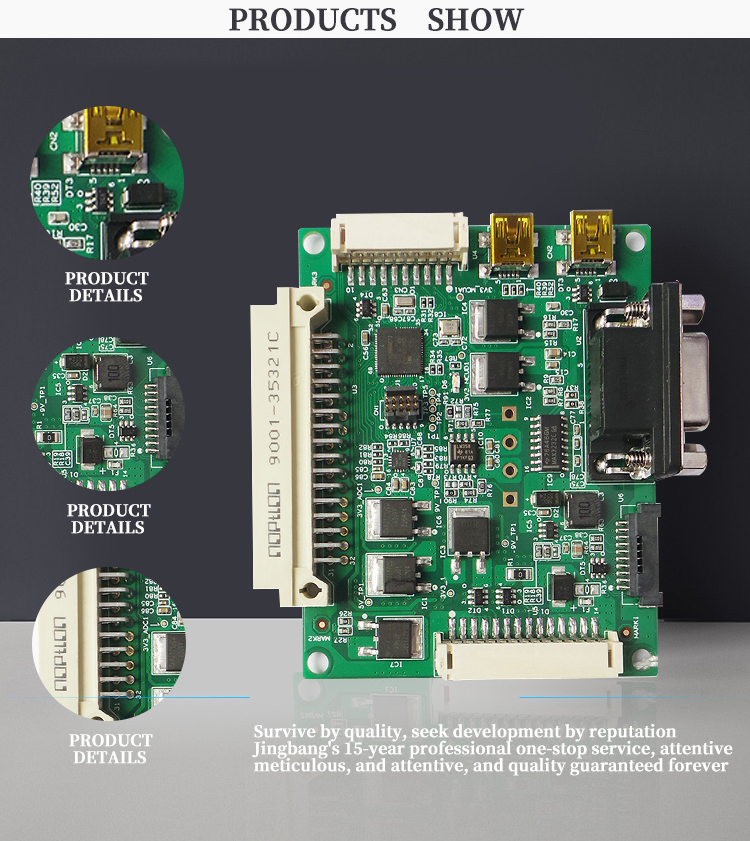

Brake system pcb control board prototype pcb manufacturing

Brake system pcb control board prototype pcb manufacturing

PCB parameter

| Article | Description | Capability | |

| Sercive | PCB and SMT assembly with one-stop service | ||

| Material | Laminate materials | FR4, high TG FR4, high frequency, alum, FPC | |

| Board cutting | Number of layers | 1-48 | |

|

Min.thickness for inner layers (Cu thickness are excluded) |

0.003”(0.07mm) | ||

| Board thickness | Standard | (0.1-4mm±10%) | |

| Min. | Single/Double:0.008±0.004” | ||

| 4layer:0.01±0.008” | |||

| 8layer:0.01±0.008” | |||

| Bow and twist | ﹤7/1000 | ||

| Copper weight | Outer Cu weight | 0.5-4 0z | |

| Inner Cu weight | 0.5-3 0z | ||

| Drilling | Min size | 0.0078”(0.2mm) | |

| Drill deviation | ±0.002″(0.05mm) | ||

| PTH hole tolerance | ±0.002″(0.005mm) | ||

| NPTH hole tolerance | ±0.002″(0.005mm) | ||

|

Solder mask

|

Color | Green,white,black,red,blue… | |

| Min solder mask clearanace | 0.003″(0.07mm) | ||

| Thickness | (0.012*0.017mm) | ||

| Silkscreen | Color | white,black,yellow,blue… | |

| Min size | 0.006″(0.15mm) | ||

| E-test | Function Test | 100% Functional test | |

| PCBA Testing | X-ray,AOI Test,Functional test | ||

| Pcb assembly | one-stop service electronic manufacxturer service | ||

| Component sourcing | Yes | ||

| Certificate | IATF16949,ISO9001 | ||

| Delivery time: | PCB | 3-12days | |

| PCBA | 8-20days | ||

| Tolerance of pcb | ±5% | ||

| Max size of finish board | 450*450mm | ||

| MOQ | NO MOQ (1pcs) | ||

| Surface Finish | HASL,ENIG,immersion silver,immersion tin,OSP… | ||

| PCB outline | Square,circle,irregular(with jigs) | ||

| package | QFN,BGA,SSOP,PLCC,LGA | ||

| Sub-assembly | Plastic,metal,screen | ||

FAQ:

For PCBA(PCB with soldered components),please provide Gerber files and also BOM (components list), and if you need us to do function test, please also provide the test instruction/procedure.

3,How long does it take for PCB and PCBA Quote?

PCBs quotation within 2 hours can finished.

The PCBA depend on the components quantity,if you order is urgently please contact us directly,we will priority to deal it and do ourbest to give you satisfied delivery time.

Products related to this product / Related Products

- HDI pcb board fabrication and assembly

- HDI pcb board is widely used in the automotive electronics industry. HDI pcb board advantages are as below 1. Can reduce the cost of PCB: when the layers of PCB increases to more than eight layers, it is manufactured by HDI, and its cost is lower than the traditional complicated lamination process.

- High frequency pcb is hot and trend in pcba industry

- High frequency pcb are special circuit boards with high electromagnetic frequencies. Generally speaking, high frequencies can be defined as frequencies above 1 GHz.

- Ceramic pcb manufacturer prototype and mass pcb production

- Ceramic pcb have good high-frequency and electrical properties, and are ideal packaging materials for next-generation large-scale integrated circuits and power electronic modules.

Related information

- Immersion Gold PCB Board and Gold Plated PCB Board Comparison

- Communication circuit module IoT base station PCB

- Business opportunities discovered from the May Day holiday

- Why say FASTPCBA is a responsible pcb manufacturer?

- PCB factories polarization situation

- PCB board assembly common matters

- COVID-19's reflection on humans

- Pcb manufacturers’ opportunities and challenges during COVID-19

- Can the PCB board be exported smoothly under the epidemic?

- The future of PCB assembly for medical prevention and control equipment

| I want to comment: | |

| *Content: |

(Content up to 500 words, 1000 characters) |

| Verification Code: | Invisibility?! |

samples

PCB Assembly

Multilayer PCB

Rigid-Flex PCB

Flexible PCB

HDI PCB

High Frequency PCBs

Gold-Plated PCB

Aluminum PCB

PCBA Board

PCB Prototype

Components

Add WeChat:18784674559

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

3/F. 1/B, 18-2 Yuquan East Rd. Yulv Village.

3/F. 1/B, 18-2 Yuquan East Rd. Yulv Village.  F:86-18784674559

F:86-18784674559

pcba13@fastpcba.cn

pcba13@fastpcba.cn

Altogether-article comment【I want to comment】