Search Products

-

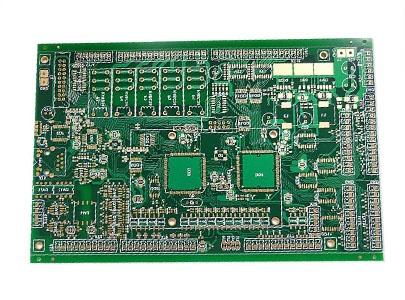

Multilayer PCB Circuit Board

Multilayer PCB or multilayer printed circuit board is a circuit board composed of two or more conductive layers (copper layers). Multilayer PCB can be divided into Multilayer Rigid PCB, Multilayer Flexible PCB, Multilayer Rigid-flex PCB. The copper layer is pressed together by the resin layer (prepreg). Due to the complexity of the multilayer PCB manufacturing process, low yield and difficulty in rework, their prices are relatively higher than single-layer and double-sided PCBs.more +

-

PCB Manufacturing Battery Management System

In the PCB manufacturing process, the quality problems that occur are basically tiny problems, because the systems involved are more complicated. Let us give a brief overview below:more +

-

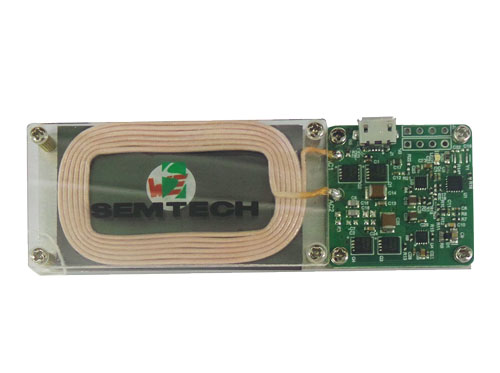

double-sided board

FASTPCBA is a PCB&PCBA processing manufacturer for 15 years.Mainly deal in PCB fabrication、PCB assembly、printed circuit board test and component sourcing.Our products apply for automotive、intelligence household、medical equipment、aerospace engineering、military application etc.more +

-

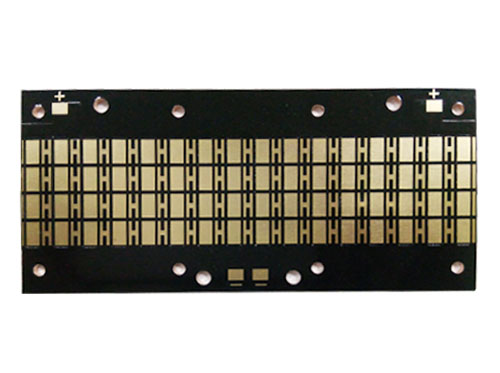

aluminum substrate

FASTPCBA is a PCB&PCBA processing manufacturer for 15 years.Mainly deal in PCB fabrication、PCB assembly、printed circuit board test and component sourcing.Our products apply for automotive、intelligence household、medical equipment、aerospace engineering、military application etc.more +

-

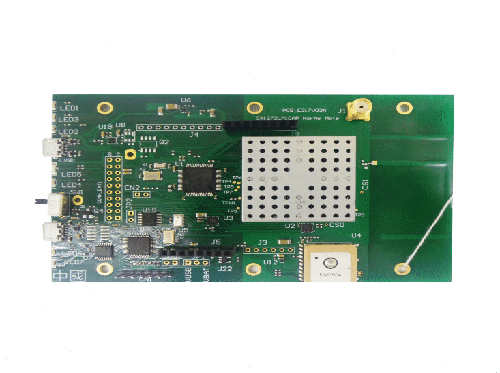

Single-Sided Board

FASTPCBA is a PCB&PCBA processing manufacturer for 15 years.Mainly deal in PCB fabrication、PCB assembly、printed circuit board test and component sourcing.Our products apply for automotive、intelligence household、medical equipment、aerospace engineering、military application etc.more +

-

Single-Sided Board

FASTPCBA is a PCB&PCBA processing manufacturer for 15 years.Mainly deal in PCB fabrication、PCB assembly、printed circuit board test and component sourcing.Our products apply for automotive、intelligence household、medical equipment、aerospace engineering、military application etc.more +

Search News

- [Company News]PCB coating reliability and failure analysis2021/07/09/ 17:38

- With the development of electronic design in the direction of lightness and thinness, the high-density integration (HDI) technology in the PCB manufacturing process makes the terminal product design more miniaturized, while meeting the requirements of electronic performance and efficiency. HDI is currently widely used in mobile phones, digital, automotive electronics and other products.

- Read(0)

- [Company News]Three key processes in HDI PCB manufacturing2021/05/05/ 14:27

- HDI board is the most precise circuit board among PCB boards, and its board manufacturing process is also the most complicated. Its core steps mainly include the formation of high-precision printed circuits, the processing of micro-vias, and the electroplating of surfaces and holes. Next, let's take a look at the core steps of HDI PCB manufacturing.

- Read(0)

- [Company News]Impact of pcb factory quick turn pcb production equipment on reflow soldering quality2019/10/09/ 15:45

- It has very close relationship between Pcb factory quick turn pcb production reflow quality and pcb manufacturing processing equipment. The main factors affecting reflow soldering quality are as follows.

- Read(0)

- [Company News]During Pcb manufacturing process, causes and precautions for poor welding2019/08/08/ 15:10

- During pcb manufacturing process, bridging connection is a conductive path formed by soldering two or more adjacent pads in contact with each other. The cause of bridging connection is mostly due to excessive solder or severe sag after solder printing, or the size of the substrate soldering area is over the tolerance, SMD placement offset, etc., SOP, QFP circuit tends to miniaturization stage, bridging connection causes electrical short circuit and affects product usage.

- Read(0)

- [Company News]Various inspection standards ensure turnkey pcb manufacturing quality2019/07/16/ 14:28

- When performing electronic processing at SMT Electronics Factory, QC will execute quality inspection after the completion of turnkey pcb manufacturing. Due to many years of quality inspection experience, inspectors generally can quickly verify the PCBA board problem. The following are the turnkey pcb manufacturing processing appearance standards summarized by the professional quality inspectors of SMT processing plants through years of processing experience.

- Read(0)

- [Company News]Turnkey pcb manufacturing process to achieve zero bad products,we should pay attention to the details2019/07/08/ 14:31

- Turnkey pcb manufacturing process to achieve zero bad products,we should pay attention to the details In the turnkey pcb manufacturing assembly process, the control and management of each link has a great impact on q...

- Read(0)

- [Company News]During turnkey pcb manufacturing process,affecting factors of raw materials2019/07/04/ 14:16

- During turnkey pcb manufacturing process,affecting factors of raw materials During turnkey pcb manufacturing process, the impact on product quality is not only the elements of manual operation, but also the...

- Read(0)

- [Company News]During the Pcb manufacturing process, what are the details that must be paid attention to?2019/07/02/ 15:51

- During the Pcb manufacturing process, what are the details that must be paid attention to? Inside each production plant, there will be an SMT processing line. On this line, we can divide into the following sections. ...

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn