Search Products

-

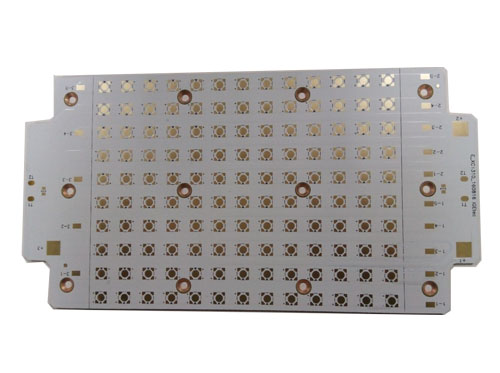

aluminum substrate

FASTPCBA is a PCB&PCBA processing manufacturer for 15 years.Mainly deal in PCB fabrication、PCB assembly、printed circuit board test and component sourcing.Our products apply for automotive、intelligence household、medical equipment、aerospace engineering、military application etc.more +

Search News

- [Company News]Smd's reflow soldering process and the benefits of IR soldering2021/07/07/ 18:05

- After infrared heating reflow soldering, generally called infrared soldering, it is mainly used for soldering substrates with surface mount components. Generally, the substrate is transported through a machine with a series of heating elements, such as rod-shaped radiators positioned transverse to the transport direction.

- Read(0)

- [Company News]PCBA solder mask is very important, what are the bad designs?2020/09/02/ 17:47

- Solder mask is a very important coating material in PCBA's work and material processing. It can provide dielectric and mechanical shielding for the PCBA board during the PCBA soldering process and after soldering, and prevent the deposition of solder at this location.

- Read(0)

- [Company News]Printed circuit board vias setting2019/12/12/ 15:10

- There are 4 types of holes for printed circuit boards: mechanical mounting holes, component pin insertion holes, isolation holes and via holes. This section mainly introduces the vias and the settings of vias when reflow and wave soldering processes are used.

- Read(0)

- [Company News]Through Hole Reflow Process (PIHR) introduction2019/12/10/ 14:19

- Through-hole component reflow soldering process (Pin-In-Hole Reflow, PIHR) is to insert pins into the insertion hole filled with solder paste and use the reflow soldering process method to achieve through-hole components and surfaces mount components (SMC / SMD) are reflowed at the same time. Compared with traditional crafts, it has great advantages in economy and advancedness.

- Read(0)

- [Company News]In PCB manufacturing,component layout direction of wave soldering process2019/12/03/ 15:38

- In order to make both ends of the PCB manufacturing components contact the solder wave at the same time, the long axis of the chip component should be perpendicular to the direction of the wave soldering machine.

- Read(0)

- [Company News]Wave soldering process parameter setting requirements2019/11/14/ 11:26

- Frequently debugging wave soldering process parameters include component surface preheating temperature, soldering surface preheating temperature, soldering temperature, contact time (also called soldering time)

- Read(0)

- [Company News]PCB manufacturing reflow soldering process requirements2019/11/11/ 15:08

- Reflow soldering is a key process for PCB manufacturing SMT and must be carried out under controlled conditions. The process requirements for reflow soldering are as follows.

- Read(0)

- [Company News]Why does the pcb supplier choose no-clean soldering process?2019/11/05/ 15:50

- With the protection of the atmospheric ozone layer, the in-depth development of Ozone Depleting Substances (ODS) and the rapid development of SMT, more and more pcb suppliers are choosing or preparing to use no-clean soldering technology, low solid content and no-wash.

- Read(0)

- [Company News]Pcb supplier reflow solder ball generation cause and solution2019/11/04/ 15:45

- In pcb supplier circuit board manufacturing, the generation of solder balls is closely linked to the soldering process of solder joints. If the gas in the solder joint does not escape in time, it may cause voiding.

- Read(0)

- [Company News]PCB soldering of PCB manufacturers2019/10/14/ 18:37

- PCB soldering ofPCB manufacturers Pcb manufacturing wave soldering principle Wave soldering process and equipment wave soldering was first invented by Fry's Metal Company of the United Kingdom in the 1950s. It is the most mature, most infl...

- Read(0)

- [Company News]Fast PCB manufacturing reflow soldering machine2019/10/08/ 11:09

- Some projects with reflow soldering machines may achieve better standards during PCB manufacturing and soldering process.

- Read(0)

- [Company News]Pcb manufacturer how to control lead-free wave soldering process2019/09/12/ 10:46

- The pcb manufacturer quality control method of wave soldering is basically the same as reflow soldering in principle, because their soldering mechanism and RC28F128K3C solder joint quality requirements are the same.

- Read(0)

- [Company News]During turnkey pcb manufacturing, double-sided reflow soldering process considerations2019/08/09/ 15:58

- At present, the mainstream circuit board assembly technology of turnkey pcb manufacturing industry should be "full-flow reflow soldering". There are other board soldering methods, and this full-board reflow soldering can be divided into single and double sided reflow soldering, single-sided reflow soldering boards are rarely used now, because double-sided reflow can save board space, which means that can be made smaller, so tmost of the boards belong to the double-sided reflow process in the market.

- Read(0)

- [Company News]For china pcb manufacturer, what are the PCBA inspection equipment?2019/07/18/ 14:50

- After completing the front-end soldering process, China pcb manufacturer cannot ensure that the PCBA board is intact. To ensure that the products shipped to the customer are intact and to improve customer satisfaction,it’s necessary to proceed inspection.

- Read(0)

- [Company News]The functions of flux in PCBA processing plants during wave soldering process2019/06/26/ 10:58

- The functions of flux in PCBA processing plants during wave soldering process Wave soldering flux is the main electronic auxiliary material used in electronic assembly PCBA processing. Its quality d...

- Read(0)

- [Company News]Surface mount soldering joint formation process and metallographic organization2019/04/19/ 14:34

- Surface mount soldering joint formation process and metallographic organization The formation of solder joints includes two processes - melting and recrystallization of the solder, and interfacial reaction. The interfacial reaction...

- Read(0)

- [Company News]Popular Science: Understanding of PCB soldering Flux Correctly2019/04/17/ 15:47

- In the welding process, the material that can clean the welding metal and the welding surface and help the welding is called flux. Flux is an indispensable craft material in the soldering process. Liquid flux is used in wave soldering and manual soldering processes. Flux and solder are used separately. In the reflow process, the flux is an important part of the solder paste. The quality of the solder is not only related to the solder alloy, components, PCB quality, soldering process, but also has a very important relationship with the performance of the flux and the flux choosing .

- Read(0)

- [Company News]Analysis of the Causes of Component Shift in SMT Processing2019/04/16/ 14:22

- The main purpose of SMT processing is to accurately mount the surface-mount components to the fixed position of the PCB. In the process of mounting processing, some process problems occur sometimes, which affects the quality of the mounting, such as the displacement of components. The displacement of the components that appear in the processing of the mounting is a foreshadowing of several other problems in the soldering process of the component board, which needs attention. So what is the reason for components shift in the SMT processing?

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn