Search Products

-

PCB Manufacturing and Assembly, SMT, DIP, Mixed Technology

With 20+ years of OEM printed circuit board ( PCB ) and PCB assembly manufacturing experience along with excellent quality, advanced services and competitive prices, FASTPCBA has won numerous customers' trust and support. As a professional EMS/OEM PCB PCBA Manufacturer, we could provide one-stop pcb assembly service.more +

-

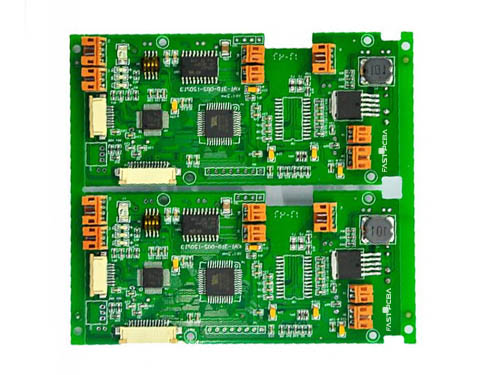

PCB and Circuit Board DIP Assembly Manufacturer

With 20+ years of OEM printed circuit board ( PCB ) and PCB assembly manufacturing experience along with excellent quality, advanced services and competitive prices, FASTPCBA has won numerous customers' trust and support. As a professional EMS/OEM PCB PCBA Manufacturer, we could provide one-stop pcb assembly service.more +

-

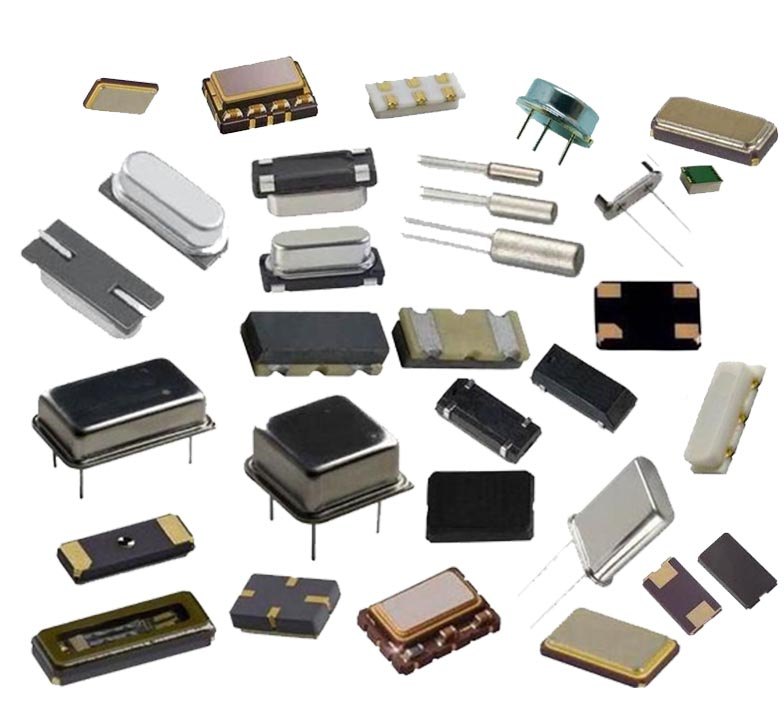

Surface mount device (SMD)

Surface-mounting devices (SMD) are developed on the basis of the original Dual Inline Package (DIP) devices. They are an important indicator for the development of through-hole technology (THT) to SMT and are also important for the development of SMT.more +

-

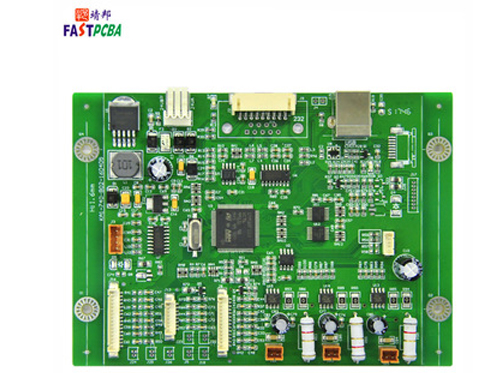

PCBA-F154

PCBA is the abbreviation of Printed Circuit Board +Assembly in English, which means that the bare pcb board mount smt components, or the whole process of DIP , referred to as PCBA. This is a common way of writing in China, and the standard writing method in Europe and America is PCB. 'A, added '', which is called the official idiom.more +

Search News

- [Posts]What are the standards for SMT and DIP assembly of components?2022/04/12/ 16:58

- What is the standard of PCBA factory in the production of component device SMT and DIP assembly? The following FASTPCBA will take you to understand the relevant precautions:

- Read(0)

- [Posts]Principle and production method of PCBA test fixture2022/02/17/ 17:39

- The PCBA test fixture (test frame) is widely used in the entire PCBA production process. It is mainly used to test the PCB board after the SMT patch and DIP plug-in are completed. Among them, the ICT test is mainly used, that is, the circuit is tested through the test point.

- Read(0)

- [Posts]What production links does one-stop PCBA processing include?2021/09/10/ 14:00

- PCBA is a series of processing processes such as PCB circuit board manufacturing, component procurement and inspection, SMT assembly, DIP assembly, program firing, testing, and aging. There are many links involved in the PCBA processing process, and the quality of each link must be controlled to produce a good PCBA circuit board.

- Read(0)

- [Company News]Introduction to the process flow of DIP assembly in PCBA processing2021/05/18/ 15:00

- With the rapid development of SMT technology, SMT processing gradually replaced DIP assembly. However, due to the large size of some electronic components in PCBA production, DIP assembly has not been replaced, and it still plays an important role in the electronic assembly process. DIP assembly is after SMT patch processing, generally using assembly line manual plug-in, which requires a lot of employees.

- Read(0)

- [Company News]How many ways are there for PCB assembly?2021/04/29/ 15:40

- PCBA processing is to form a finished electronic product after a complete set of processing processes such as PCB boarding, SMT chip processing, DIP plug-in processing, quality inspection, testing, and assembly. This processing process is called PCBA processing, and PCBA can also be said to be this The processed circuit board.

- Read(0)

- [Company News]What is the process from bare PCB to PCBA?2021/04/06/ 17:51

- SMT is a Surface Mounted Technology, which is one of the most popular technologies and processes in the electronics assembly industry. Simply put, it is a kind of surface mount components without leads or short leads (SMC/SMD for short, chip components in Chinese) mounted on the surface of a Printed Circuit Board (PCB) or the surface of other substrates Above, the circuit assembly technology that is assembled by soldering and assembling by reflow soldering or dip soldering.

- Read(0)

- [Company News]What do DIP and SIP mean in PCB?2021/02/22/ 18:19

- Packaging refers to connecting the circuit pins on the silicon chip to the external joints with wires to connect with other devices. The package form refers to the case for mounting semiconductor integrated circuit chips. It not only plays the role of installation, fixing, sealing, protecting the chip and enhancing the electric heating performance, etc.

- Read(0)

- [Company News]One-stop DIP assembly service2021/02/02/ 14:06

- DIP assembly is one of the main businesses of Shenzhen Jingbang Electronics Co., Ltd. The factory is equipped with advanced equipment. According to different needs, manual plug-in or AI automatic plug-in can be used for processing and production to meet different processing needs to a certain extent. Meet the ISO9001 standard, lead-free process.

- Read(0)

- [Company News]DIP assembly and process flow2020/12/30/ 10:42

- The dual in-line package is also called DIP assembly, or DIP for short. It is an integrated circuit assembly method. The shape of the integrated circuit is rectangular, and there are two parallel rows of metal pins on both sides, called pin headers. DIP assembled components can be soldered in the through holes plated on the printed circuit board or inserted into the DIP socket.

- Read(0)

- [Posts]What is DIP assembly? What are the characteristics of DIP?2020/12/22/ 16:51

- DIP is one of the basic components of electronic components. It is called dual in-line assembly technology. It refers to the integrated circuit chip assembled in the dual in-line form, which is also used in most small and medium-sized integrated circuits. The number of pins generally does not exceed 100.

- Read(0)

- [Company News]How long is the shelf life of pcba circuit boards?2020/12/14/ 15:32

- PCBA is the abbreviation of Printed Circuit Board Assembly, which means that the bare PCB board passes through the SMT assembly or the entire process of DIP plug-in, referred to as PCBA. More people pay attention to the service life of pcba and the reliability of high frequency operation. Few people will know about its shelf life. Today, now FASTPCBA technical engineer will come to tell you about this. In general, the shelf life of PCBA is 2 to 10 years.

- Read(0)

- [Posts]SMT processing requirements for PCB design2020/11/28/ 09:18

- As we all know, SMT processing has requirements for PCB design. Only PCB boards designed through reasonable specifications can give full play to the processing capabilities of SMT equipment and achieve efficient PCBA processing.

- Read(0)

- [Company News]How to improve the PCBA board welding method2020/11/09/ 16:28

- PCBA is the abbreviation of Printed Circuit Board Assembly, which means that the empty PCB board passes through the SMT assembly or the entire process of DIP plug-in, referred to as PCBA.

- Read(0)

- [Company News]Four issues that need attention in PCBA processing2020/09/28/ 11:32

- Four issues that need attention in PCBA processing. 1. MT patch assembly; 2. DIP plug-in welding; 3.test and program firing; 4. PCBA manufacturing and test.

- Read(0)

- [Posts]What are the main two aspects of PCBA processing quality control?2020/09/25/ 17:42

- The entire process of PCBA processing includes PCB circuit board processing, SMT placement, component procurement and inspection, DIP plug-in post-welding, burning test, aging, assembly and other processes. The entire processing procedure involves a wide range of quality control details.

- Read(0)

- [Company News]Principles and methods of PCBA processing quotation2020/09/03/ 17:22

- PCBA cost = PCB board cost + PCB testing fee + PCB engineering fee (applicable for small batches) + component purchase cost + SMT/DIP welding fee + PCBA testing fee + pcb assembly engineering fee (for small batches) + special packaging and logistics costs ( If the customer needs).

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn