Search Products

-

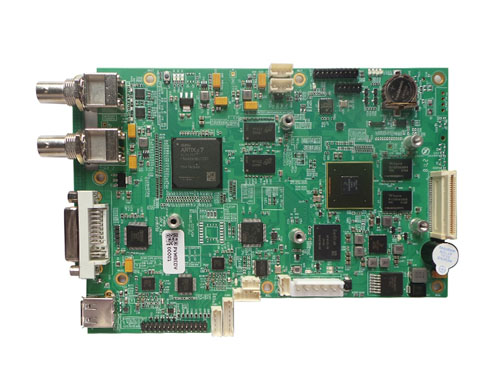

PCBA Services Surface Mount Technology Electronics Manufacturing

With 20+ years of OEM printed circuit board ( PCB ) and PCB assembly manufacturing experience along with excellent quality, advanced services and competitive prices, FASTPCBA has won numerous customers' trust and support. As a professional EMS/OEM PCB PCBA Manufacturer, we could provide one-stop pcb assembly service.more +

-

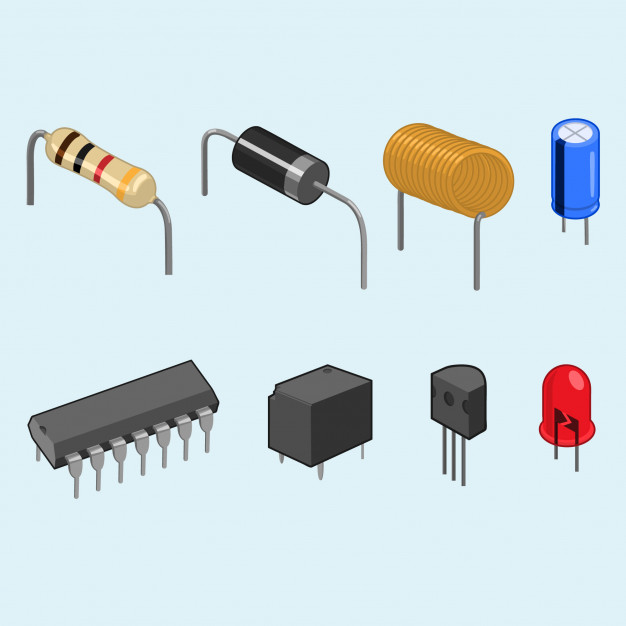

Surface mount component package category

The package structure of SMD components is the basis of process design. According to the structure of pins or solder joints, it can be divided into: Chip type J-shaped pin type, L-shaped pin type, BGA type, BTC type, castle type.more +

Search News

- [Posts]Solder Joint Quality Inspection in SMT PCB Assembly2022/03/24/ 15:48

- The quality of solder joints is very important in SMT (Surface Mount Technology) pcb assembly. The quality of solder joints can directly see the effect of soldering, and the quality of SMT assembly can be directly seen from the quality of solder joints. The improvement in ensuring the quality of solder joints in electronic processing is always on the move and never stops.

- Read(0)

- [Company News]Comparison of SMT and traditional through-hole technology2021/03/15/ 16:26

- Surface mount technology (SMT) is used almost exclusively by PCB components, and for good reasons. SMT is a fast, fully automated process that can improve the accuracy of component placement, reduce manual labor, provide consistent quality and reduce costs.

- Read(0)

- [Posts]PCBA process: prevent failures caused by reflow soldering2021/01/04/ 17:19

- Reflow soldering is a surface mount technology (SMT) process that is used to connect components to the top layer of the PCB. For double panels, the bottom layer is the same. The process involves running the circuit board through an oven and going through a four-stage profile: preheating, soaking, reflow, and cooling.

- Read(0)

- [Posts]What is the smt production line?2020/12/15/ 16:01

- SMT production line, also called Surface Mount Technology, is a new generation of electronic assembly technology developed from hybrid integrated circuit technology. It is characterized by the use of component surface mount technology and reflow soldering technology, and has become a new generation of assembly technology in electronic product manufacturing.

- Read(0)

- [Posts]What is the difference between SMD and SMT?2020/11/17/ 16:20

- Surface Mount Technology (SMT) is essentially a method of placing components on a circuit board. Modern SMT assembly technology is smaller, more efficient and faster to operate. Surface Mount Device (SMD) is the actual component mounted on the circuit board according to the specific component.

- Read(0)

- [Company News]What is smt assembly meaning2020/11/03/ 09:51

- SMT is called Surface Mount or Surface Mount Technology. It is the most popular technology and craft in the electronics assembly industry.

- Read(0)

- [Posts]What is SMT patch?2020/10/10/ 16:05

- SMT is the surface mount technology (Surface Mounted Technology) (abbreviation of Surface Mounted Technology), which is the most popular technology and process in the electronics assembly industry.

- Read(0)

- [Company News]What are the typical SMT processes?2019/11/04/ 15:25

- What are the typical SMT processes? A printed circuit board assembly that is assembled using surface mount technology is called a Surface Mount Assembly (SMA). Due to the different requirementsof high density, versatility and high reliabil...

- Read(0)

- [Company News]Surface mount technology requirement for adhesive glue2019/10/19/ 17:47

- In order to ensure the reliability of surface assembly, the adhesive glue should meet the following requirements.

- Read(0)

- [Company News]SMT2019/08/23/ 16:04

- SMT is the abbreviation of Surface Mount Technology, which is the meaning of surface mount technology. It is a popular technology and process in the electronic assembly industry. The main features of SMT are high assembly density, small pro...

- Read(0)

- [Company News]Hazards of ESD during SMT processing2019/06/13/ 11:51

- Hazards of ESD during SMT processing What are the hazards of ESD during SMT processing? ANSI/ ESD S20.20 are the electrostatic protection standard for SMT production and electronic products processing ...

- Read(0)

- [Company News]SMT solder paste preservation method and correct usage2019/05/28/ 13:50

- SMT solder paste preservation method and correct usage SMT solder paste preservation method: First,solder paste preservation: Since the solder paste is a chemical product, it must be stored in a 5-8 degree refrig...

- Read(0)

- [Company News]PCB assembly signal integrity design method2019/05/20/ 14:05

- PCB assembly signal integrity design method As the output switching speed of integrated circuits increases and the density of PCB boards increases, Signal Integrity has become one of the issues that must be concerned with...

- Read(0)

- [Company News]AOI inspection in SMT process2019/05/07/ 11:35

- AOI inspection in SMT process To ensure the quality of SMT processing products, inspection during processing is critical. In recent years, AOI testing has developed rapidly and has become the mainstream testing equipment for v...

- Read(0)

- [Company News]How to choose SMT mounting processing components reasonably2019/04/19/ 14:01

- The selection and design of SMT surface mount components is a key part of the overall design of the product.

- Read(0)

- [Company News]Keep it! Proceed surface mount technology material management In this way, the boss are willing to award you RMB100000 !2019/04/18/ 14:13

- Keep it! Proceed surface mount technology material management In this way, the boss are willing to award you RMB100000 ! Material management systems are an integral part of SMT production and are critical to business deci

- Read(0)

- [Company News]Methods for Quickly Distinguishing Common SMT mounted Components2019/02/26/ 14:34

- With the development of SMT mounted technology to miniaturization and high efficiency, various common components are getting more and more smaller. The commonly used patch resistors, inductors and capacitors are difficult to distinguish in...

- Read(0)

- [Company News]Why does SMT need to reflow the reflow carrier and the full process carrier?2018/11/09/ 15:34

- Why does SMT need to reflow the reflow carrier and the full process carrier? The reason why PCB will bend and deform during reflow soldering is because the PCB used in our lead-free process is only Tg150, which means that the sh...

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn