Search Products

-

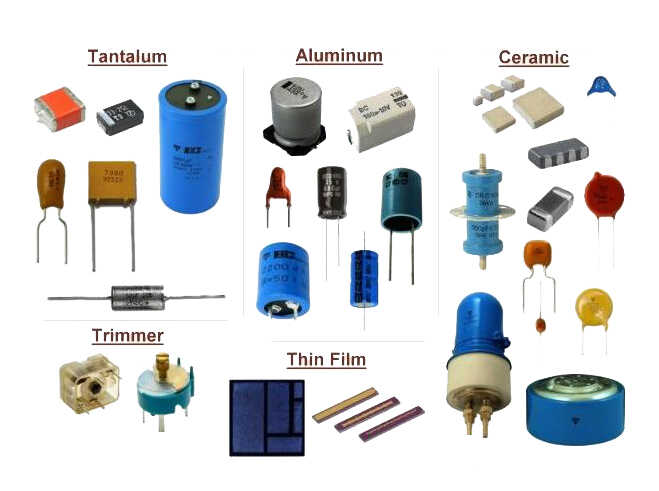

Capacitor classification

A variety of capacitors are needed in the electronic product PCB manufacturing, which play different roles in the circuit. Although there are many types of capacitors, their basic structure and principle are the same.more +

-

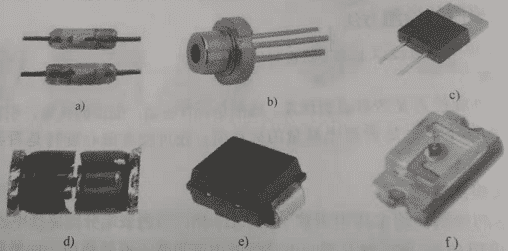

Diode classification

Diodes can be classified according to their application, manufacturing materials, manufacturing process and working principle. They can be divided into rectifier diodes, Zener diodes, detector diodes, light-emitting diodes, switching diodes and photodiodes according to their applications.more +

-

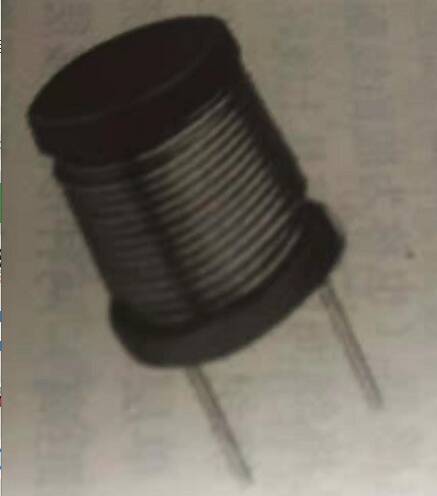

Inductor classification

Inductors can be divided into fixed inductors and adjustable inductors according to their functions. According to the core material, they can be divided into hollow cores, magnetic cores and iron core inductors. According to their different structures, can be divide into wirewound inductors and non-wire wound inductors. Device. Commonly used inductors are: fixed inductors,adjustable inductors, magnetic balls, color ring inductors, chip inductors, etc.more +

-

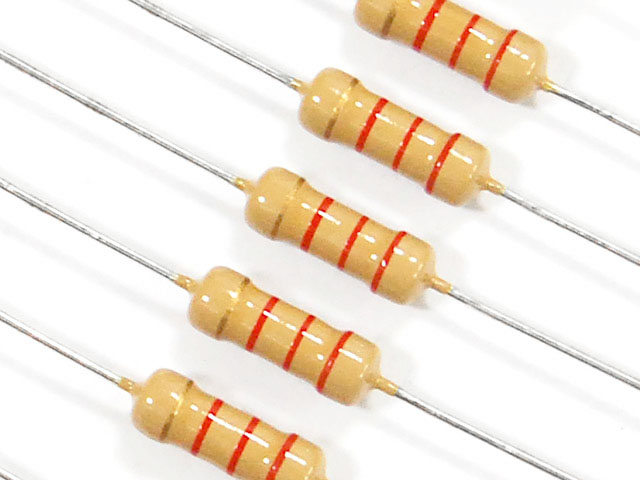

Classification of resistors

Resistors used in the manufacture of PCB electronics are typically solid resistors, thin film resistors, and wirewound resistors. Ordinary fixed resistors have only two pins, and the pins have no positive or negative polarity.more +

-

PCB assembly for explosion-proof infrared gas analyzer

Brand Name: fastpcba Base Material: Fr4 Copper Thickness: 1OZ Board Thickness: 3mm Min. Hole Diameter: 0.1mm Min. Line Width: 3 mil Surface Finishing: OSP, HASL, immersion gold/ Cu/ Ag/ Tinmore +

Search News

- [Company News]Comparison of SMT and traditional through-hole technology2021/03/15/ 16:26

- Surface mount technology (SMT) is used almost exclusively by PCB components, and for good reasons. SMT is a fast, fully automated process that can improve the accuracy of component placement, reduce manual labor, provide consistent quality and reduce costs.

- Read(0)

- [Company News]Printed Circuit Boards Thermal Design Introduction2019/11/16/ 11:36

- Electronic devices will get hot during work. The failure rate of electronic products increases exponentially with increasing operating temperature. In general, high temperatures can degrade insulation performance, component damage, thermal aging of materials, cracking of low-melting welds, and loss of solder joints, ultimately leading to failure of electronic equipment. The purpose of the heat dissipation design is to control the temperature of all electronic components inside the product so that it does not exceed the maximum temperature specified by the standards and specifications under the working environment.

- Read(0)

- [Company News]Wave soldering process parameter setting requirements2019/11/14/ 11:26

- Frequently debugging wave soldering process parameters include component surface preheating temperature, soldering surface preheating temperature, soldering temperature, contact time (also called soldering time)

- Read(0)

- [Company News]Why does the pcb supplier choose no-clean soldering process?2019/11/05/ 15:50

- With the protection of the atmospheric ozone layer, the in-depth development of Ozone Depleting Substances (ODS) and the rapid development of SMT, more and more pcb suppliers are choosing or preparing to use no-clean soldering technology, low solid content and no-wash.

- Read(0)

- [Company News]Prototype pcb manufacturing, how to control PCB and components before wave soldering?2019/11/02/ 11:30

- For printed circuit boards that have been placed for a long time, the surface is generally cleaned, which improves the solderability of prototype pcb manufacturing, reduces virtual soldering and bridging. For component leads that have a certain degree of oxidation on the surface, the surface oxide should be removed firstly.

- Read(0)

- [Company News]Online pcb manufacturing component incoming inspection2019/11/01/ 16:07

- The performance and appearance quality of online pcb manufacturing components have a direct impact on the reliability of surface mount components. The incoming materials inspection must first check the components according to relevant standards and specifications

- Read(0)

- [Company News]SMT manufacturing advantages2019/10/31/ 18:09

- SMT manufacturing surface mount components are much smaller than traditional through-hole components. In general, the surface assembly technology can reduce the size of electronic products by about 60% and reduce the weight by about 80%.

- Read(0)

- [Company News]PCB manufacturing companies clean - free flux requirements2019/10/30/ 17:40

- In order to make the soldered PCB meet the specified quality requirements without cleaning, the selection of flux is the key. PCB manufacturing companies usually have the following requirements for the solders without cleaning

- Read(0)

- [Company News]Modern electric circuit board components packaging development2019/10/29/ 14:48

- The electric circuit board products are developing towards portable, miniaturized, networked and multimedia. This market demand puts forward corresponding requirements for circuit assembly technology.

- Read(0)

- [Company News]Pcb supplier component picking error reason and solution2019/10/18/ 21:11

- Therefore, the pcb supplier should correctly input the "component start position, pitch, component number" of "component data".

- Read(0)

- [Company News]PCB manufacturer SMT processing online test equipment (ICT) introduction2019/09/28/ 13:31

- SMT In-Circuit Test (ICT) is a standard test method used by PCB manufacturers to check PCB manufacturing defects and component defects by testing the electrical performance and electrical connections of online components.

- Read(0)

- [Company News]Pcb assembly PCB component adjustment method2019/09/23/ 09:25

- First of all, the mechanical adjustment of PCB assembly PCB components, nozzle rotation adjustment direction, this method can achieve limited accuracy, it’s not suitable for future models.

- Read(0)

- [Company News]Basic knowledge of PCB design2019/09/21/ 09:15

- Since the mid-1950s, PCB technology has been widely adopted.At present, PCB has become the "mother of electronic products", and its application is almost permeated in various terminal fields of the electronic industry, including industrial control, medical equipment, automotive electronics, smart home and many other fields.

- Read(0)

- [Company News]PCB manufacturer's placement machine low efficiency reasons and solutions2019/08/24/ 09:59

- The placement efficiency of the placement machine is affected by many factors. It is suggested that the pcb manufacturer conduct a comprehensive inspection of the placement machine. Generally speaking, this phenomenon is the cause of the failure of a certain part. Here, the pcb manufacturers should be specially reminded of SMT machine nozzles must be regularly maintained.

- Read(0)

- [Company News]Why should there be a serpentine trace on the PCB?2019/07/09/ 16:54

- Any trace on the PCB will cause a time delay to the signal when passing through a high-frequency signal. The main function of the serpentine trace is to compensate for the lesser delays in the "same group of related" signal lines. Usuall...

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn