Search Products

-

Medical equipment pcb circuit board

Medical equipment pcb circuit board Product category: Medical equipment pcb circuit board Layers: 4 layers Board thickness: 0.35mm Surface treatment: Immersion gold Process characteristics: thin plate + hole in the plate Detailed process features: inner core material. 1H / HOZ (including copper), minimum drill bit 0.15, 0.25 hole needs plated hole in plate, minimum BGA 0.2mm.more +

-

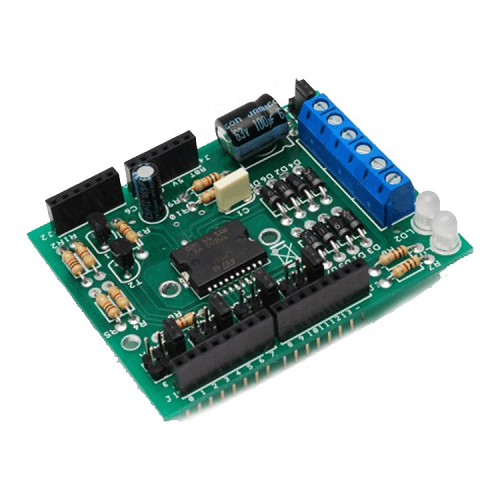

Custom circuit board cost prototype circuit board assembly pcb m

If you want to do custom circuit board manufacturing, FASTPCBA is the best choice for you. Our capacity:by virtue of 0.1mm laser drilling, the placement speed of 70000 points per hour, accurately welding 0201 size components, identifying BGA with 0.25mm distance and connector with 0.2mm distance.more +

-

Surface mount component package category

The package structure of SMD components is the basis of process design. According to the structure of pins or solder joints, it can be divided into: Chip type J-shaped pin type, L-shaped pin type, BGA type, BTC type, castle type.more +

-

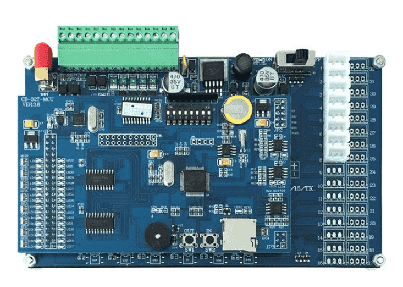

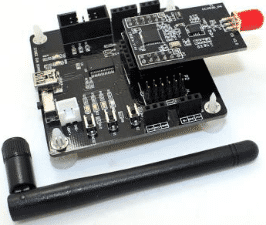

Pcb prototype china elevator card controller

FASTPCBA has many experienced engineers in the PCB industry, specializing in single/double/multilayer, rigid/flexible, HDI, BGA, hybrid PCB board manufacturing. Can provide customers with BOM and Gerber file pre-verification improvement, SMT processing, pcb prototype china, PCB manufacturing, assembly, testing, shell packaging and other worry-free one-stop service.more +

-

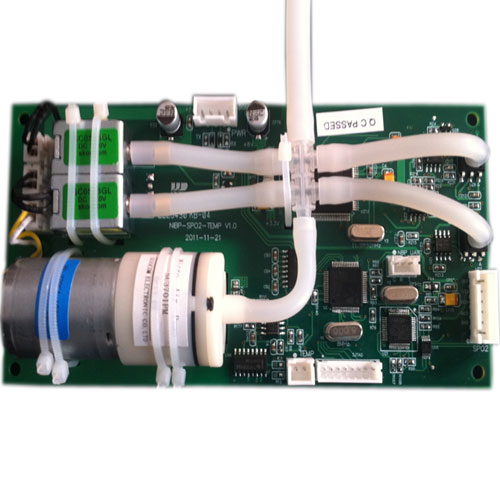

Prototype pcb assembly for multi-channel non-invasive blood pres

FASTPCBA has many engineers who have been engaged in PCB&prototype pcb assembly one-stop service for many years. It is professional and reliable in single/double/multilayer PCB, HDI PCB, BGA, hybrid PCB, heavy copper pcb and can provide pcb turkey service of PCB manufacturing, prototype pcb assembly and testing , shell packaging, SMT processing for customers.more +

-

Fr4 pcb for Amplifier device module

FASTPCBA manufacture various pcb, including FR4 circuit board, ceramic pcb, aluminum pcb, BGA etcmore +

Search News

- [Posts]The importance of using SPI solder paste inspection machine in SMT process2022/03/21/ 16:31

- As today's advanced processes tend to use smaller components, such as 01005, μBGA or PoP, the use of SPI solder paste inspection machines in SMT production processes is particularly important and will become a standard process for quality assurance.

- Read(0)

- [Posts]Why is X-ray inspection required during PCB assembly ( PCBA )?2021/11/26/ 17:15

- In recent years, area array components such as BGA, QFN, CSP and flip-chip have become more and more widely used in the field of electronics manufacturing. For example, BGA, compared with other components, has many pins, smaller inductance and capacitance between pins, and better heat dissipation performance.

- Read(0)

- [Company News]What is BGA in the PCB industry?2021/04/02/ 16:38

- The full name of BGA is Ball Grid Array (PCB with ball grid array structure), which is a pin packaging method for large components. It is similar to the four-sided pins of QFP and is connected to the circuit board by SMT solder paste soldering.

- Read(0)

- [Company News]What is the ENIG process of the circuit board?2021/03/09/ 17:05

- ENIG (Electroless Nickel Immersion Gold) is a process used for surface treatment of circuit boards. It is generally referred to as "nickel immersion gold plate" or "electroless gold plate" for short. It is currently widely used in circuit boards installed in mobile phones. Above, some BGA carrier boards will also use ENIG.

- Read(0)

- [Company News]PQFN printing, mounting and rework process2019/12/11/ 11:58

- The assembly process of PQFN (Plastic Quad Flat No-lead) is similar to BGA. CSP, because there is a large thermal pad on the bottom of the device, and the bottom electrode does not have the buffer function of the solder ball, so the coplanarity requirements are stricter. So it’s more difficult to assemble it than CSP

- Read(0)

- [Company News]BGA rework process2019/12/07/ 10:21

- Since the solder joint of the BGA is at the bottom of the device, it is invisible, so it is more difficult to rework compared to QFP and other peripheral pins. It is not a big problem when disassembling the BGA. However, when re-soldering the BGA, the rework system is required to be equipped with a spectroscopic vision system (also known as the bottom reflection optical system) to ensure accurate centering when mounting the BGA. The equipment suitable for rework BGA includes hot air rework station, infrared heating rework station, hot air Infrared rework system, etc.

- Read(0)

- [Company News]Prototype pcb manufacturing BGA package category and process characteristics2019/10/25/ 16:06

- The BGA package is available in PBGA, TBGA, CBGA, FBGA and other categories. PBGA and CBGA will undergo "dynamic deformation" during welding due to the different layered structure of the package and the coefficient of thermal expansion (CTE) of each layer of material. That is, Deformation will occur with increasing temperature during the re-flow soldering of prototype pcb manufacturing due to warping.

- Read(0)

- [Company News]How to set smt soldering circuit board welding temperature profile?2019/10/14/ 20:56

- For smt soldering circuit board lead or lead-free process, why should there be a 11 ° C-12 ° C overheating? There are two reasons, one is to ensure that the BGA package completes the second collapse......

- Read(0)

- [Company News]Regarding the BGA capsulation, you must read this article2019/06/21/ 17:25

- As electronic products move toward miniaturization, portability, and high performance, higher requirements are placed on circuit assembly technology and I/O pin number. Chips volume are getting smaller and smaller and more and more pins which bring difficulties for production and repairing. In order to adapt to the rapid growth of the number of I / O, the new capsulation form - Ball Grid Array (BGA) was put into practical usage in the early 1990s. More information and discounts pls visit: http://www.jbpcba.com or send inquiry directly to pcba23@pcb-smt.net

- Read(0)

- [Company News]what should be paid attention to when drawing PCB diagram from the welding angle2019/06/04/ 14:52

- what should be paid attention to when drawing PCB diagram from the welding angle(2) Factors affecting PCB welding quality From PCB design, all components welding to a high-quality circuit b...

- Read(0)

- [Company News]PCB assembly PBGA (CPU processor)2019/05/21/ 16:29

- PCB assembly PBGA (CPU processor) The Plastic BGA carrier is a common printed board substrate, generally a 2-4 layer organic material multilayer board. The chip is connected to the upper surface of the carrier by wire ...

- Read(0)

- [Company News]BGA PCB board assembly2019/05/21/ 16:06

- BGA PCB board assembly Definition: The A full name of BG is BALL Grid Array, which is a kind of encapsulation method for integrated circuits using organic carrier boards. Advantage: 1. Small encapsulation a...

- Read(0)

- [Company News]BGA pad design2018/11/10/ 11:39

- BGA pad design 1. Design the SMD pads on the outermost ball of the BGA. If you can, it would be better to design the outer two rows of tin balls in the four corners of the BGA as SMD pads. Only SMD pads will reduce the space for signal rou...

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn